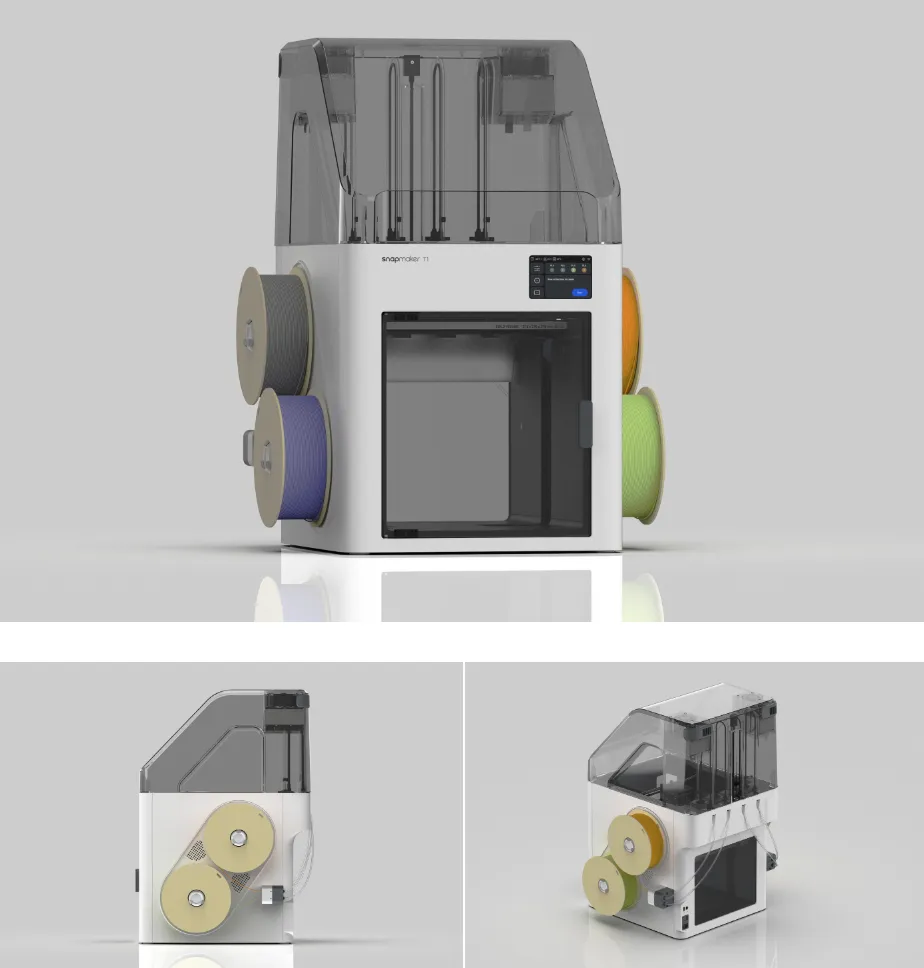

Quad-Material 3D Printing four independent filament channels for multi-color and soluble support printing

High-Speed Performance up to 300mm/s print speed with 20,000mm/s² acceleration

Enclosed Precision Build Chamber improved thermal stability for consistent, high-quality results

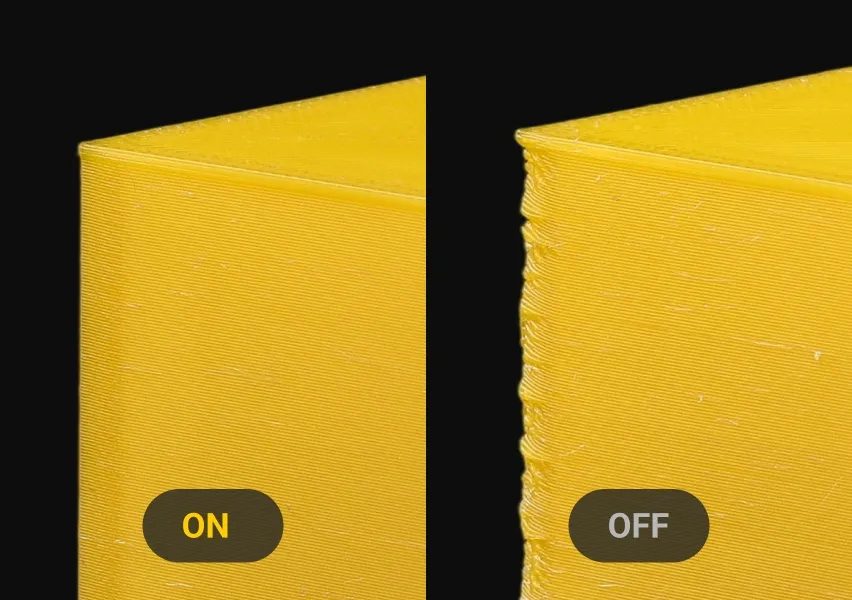

Advanced Motion & Vibration Control reduces ringing and ensures smooth surface finish

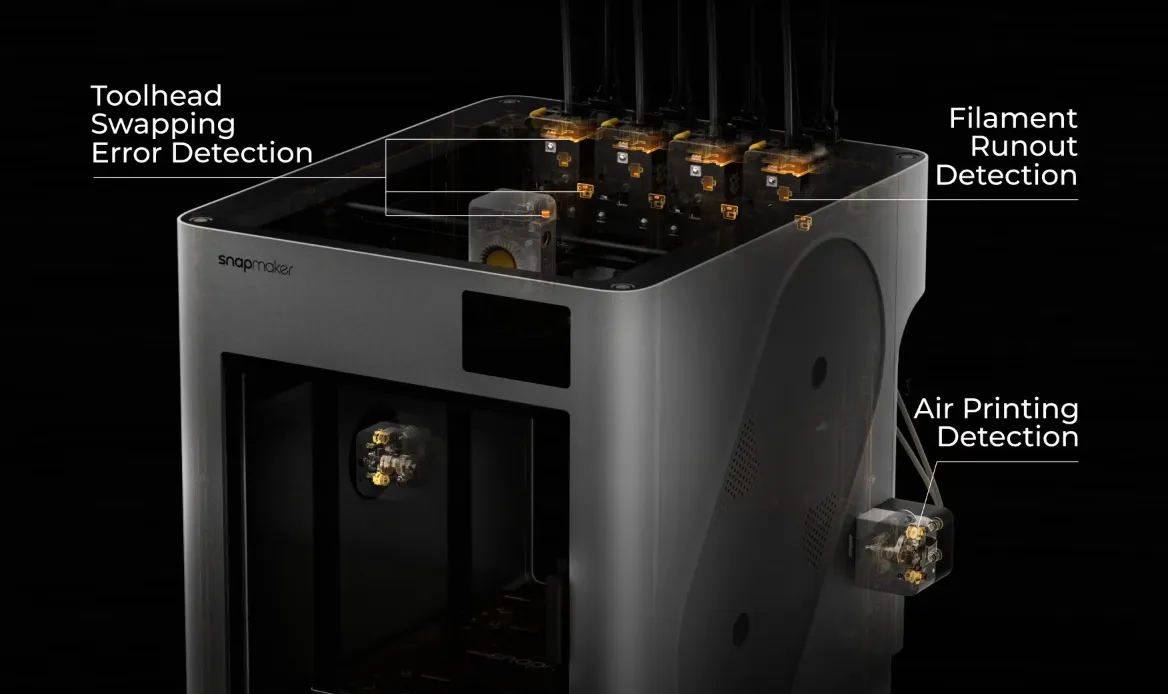

Intelligent Monitoring System filament runout detection and toolhead error protection

Looking for other products of Snapmaker?

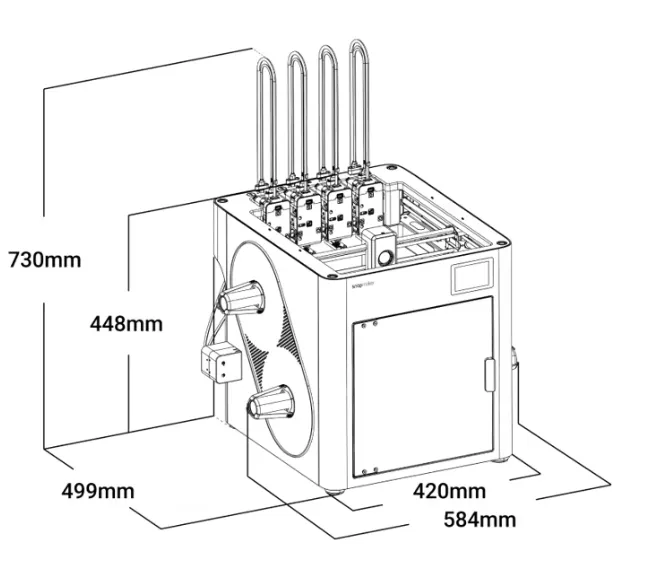

Specification

General Specifications

| Product Specifications | Snapmaker U1 Multi-Toolhead 3D Printer |

|---|---|

| Motion System | CoreXY System with Carbon Fiber X-axis Rails |

| Maximum Print Speed | Up to 500 mm/s |

| Build Volume | 270 × 270 × 270 mm |

| Number of Toolheads | 4 Independent Toolheads |

| Toolhead Swap Time | Approx. 5 Seconds (SnapSwap™ System) |

| Toolhead Offset Accuracy | Within 0.04 mm |

| Extrusion Technology | Pressure Advance with Dynamic Flow Control |

| Vibration Control | Input Shaping with Accelerometer Sensor |

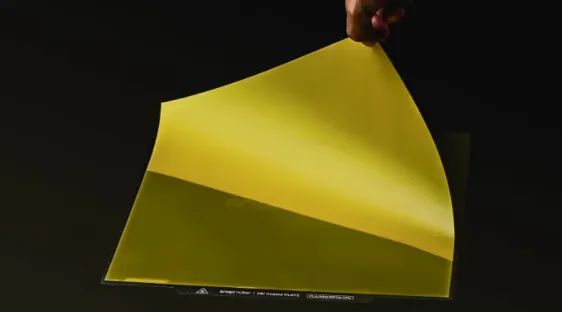

| Bed Leveling | Automatic Mesh Bed Leveling |

| Filament System | Automatic Filament System (Up to 4 Spools Standby) |

| Filament Loading | Auto-loading |

| Filament Backup Mode | Supported |

| RFID Recognition | Supported |

| Multi-Material Printing | Independent Multi-Material & Multi-Color Printing |

| Material Combinations | PETG / PLA / TPU / PVA (Mix & Match Support) |

| Purge Waste Reduction | Up to 80% Less Waste Compared to Traditional Color Switching |

| Waste Efficiency | Up to 5× Less Filament Usage |

| Speed Efficiency | Up to 6× Faster Than Conventional Multi-Color Printing |

| Print Monitoring | Built-in Chamber Camera with AI Monitoring (OTA Update Planned) |

| Anomaly Detection | Multi-Sensor Anomaly Detection & Alert System |

| Remote Control | Snapmaker App Remote Control & Time-Lapse Capture |

| Slicing Software | Snapmaker Orca (Based on Orca Slicer) |

| Structural Locking System | Steel-Ball Kinematic Couplings (Tested Over 1,000,000 Swaps) |

Description

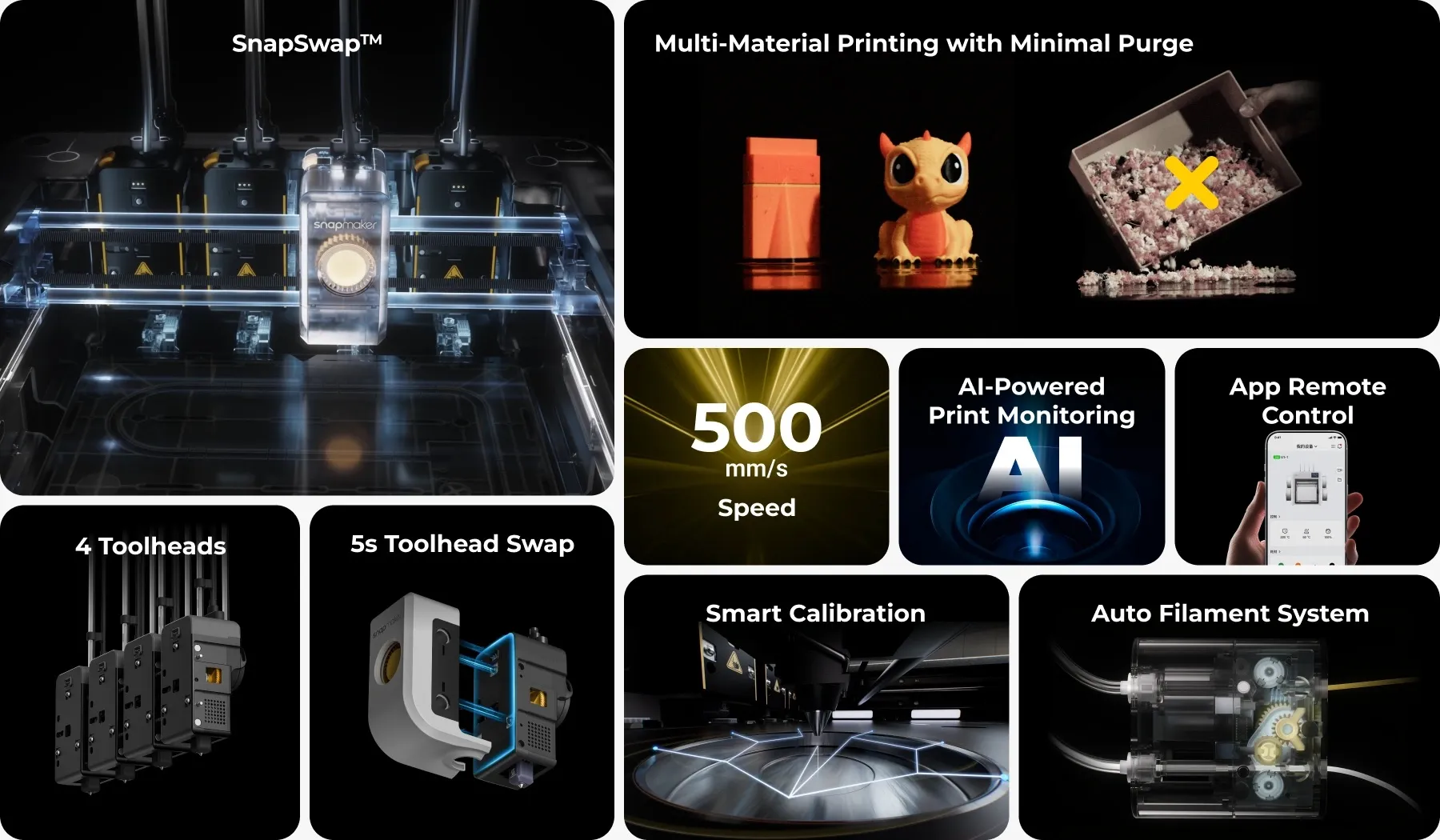

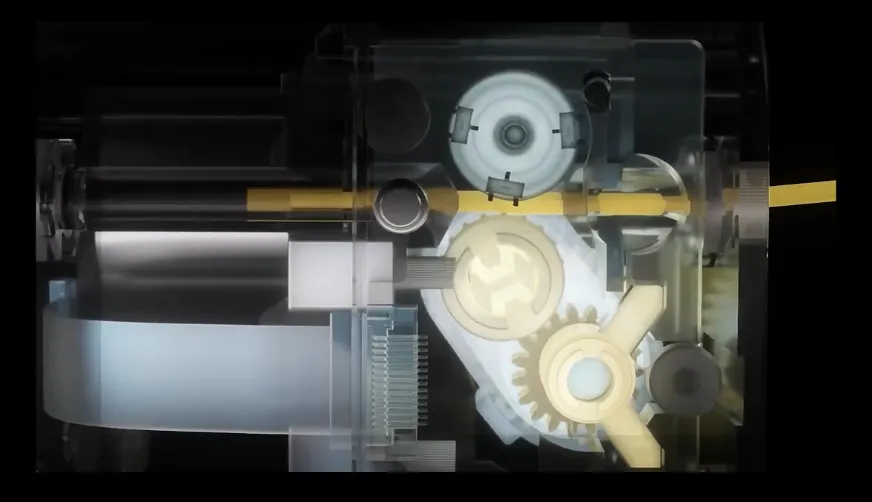

SnapSwap™ 5-Second Toolhead System

The Snapmaker U1 features an innovative SnapSwap™ system that allows toolheads to be exchanged in approximately five seconds. This quick-swap design reduces downtime between materials and enables efficient multi-color and multi-material printing workflows.

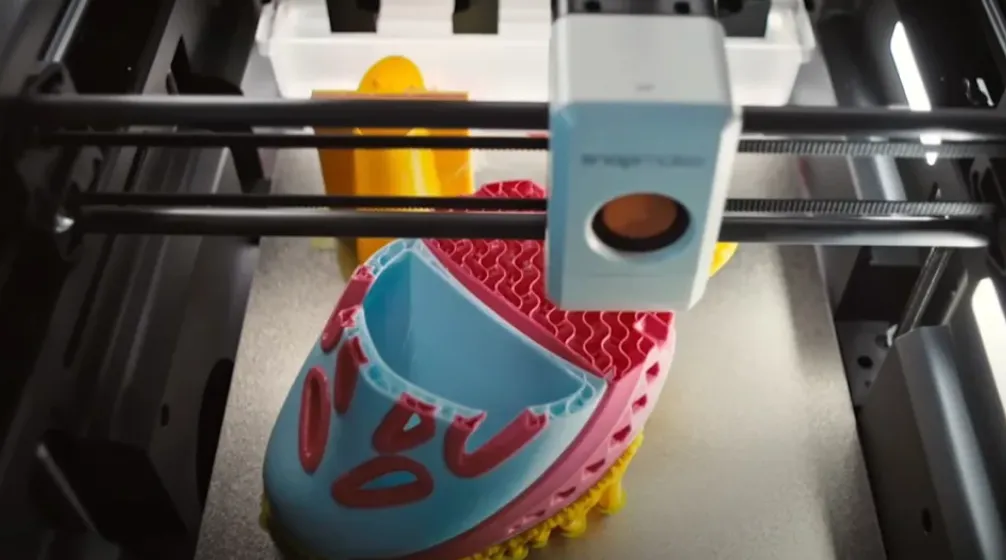

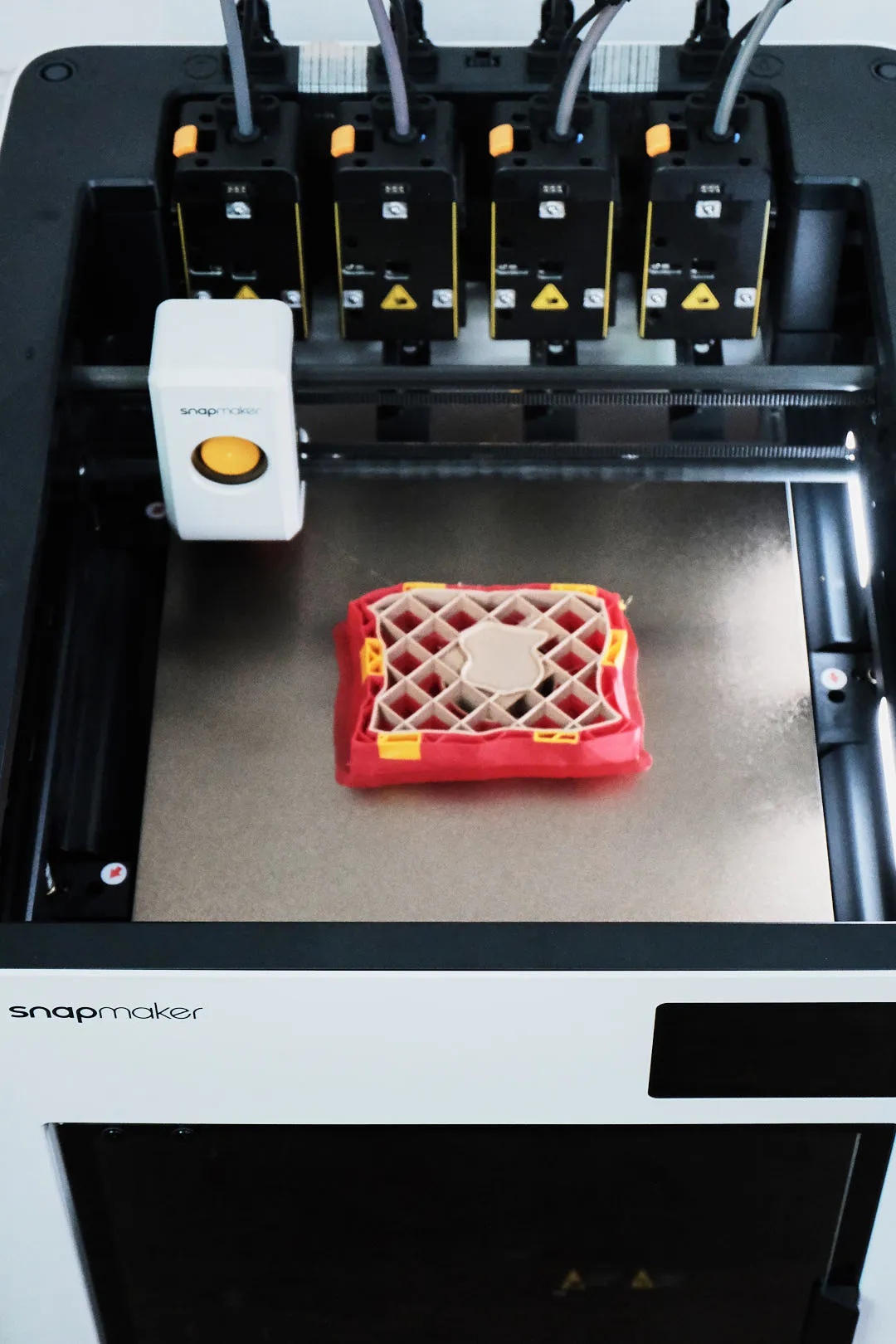

4 Independent Toolheads for True Multi-Material Printing

Equipped with four independent extruders, the U1 enables flexible combinations of colors and materials in a single print. Users can combine rigid and flexible filaments such as PLA, PETG, and TPU for advanced multi-material applications.

500 mm/s High-Speed CoreXY Motion

Built on a CoreXY motion system with rigid linear rails, the Snapmaker U1 delivers printing speeds up to 500 mm/s within a 270 × 270 × 270 mm build volume, balancing speed and dimensional precision.

Reduced Filament Waste Architecture

Filament-changing printers ‘purge’ by wasting perfectly good filament—pushing one color through the nozzle until the last trace of the old one is gone. The U1 doesn’t play that game. It only purges the tiny amount of filament that’s actually degraded by the time a new print job begins, or during flow-rate calibration, cutting waste by up to 80%[4] on every print.

| Category | Metric | Snapmaker U1 | Others* |

|---|---|---|---|

| Toys | Filament Usage | 65g | 298g |

| Annual Cost | $51 | $232 | |

| You Save | $182 / Year | ||

| Hobbies | Filament Usage | 435g | 1,053g |

| Annual Cost | $339 | $821 | |

| You Save | $482 / Year | ||

| Life Hacks | Filament Usage | 223g | 1,324g |

| Annual Cost | $174 | $1,033 | |

| You Save | $859 / Year | ||

* “Others” refers to 3D printers that use a filament changer to swap materials.

* Based on PLA filament at an average cost of $15/kg, printing one model per week.

Smart Toolhead Offset Calibration

Automatic toolhead offset calibration keeps each extruder aligned within tight tolerances, helping maintain sharp transitions between colors and materials in multi-extrusion prints.

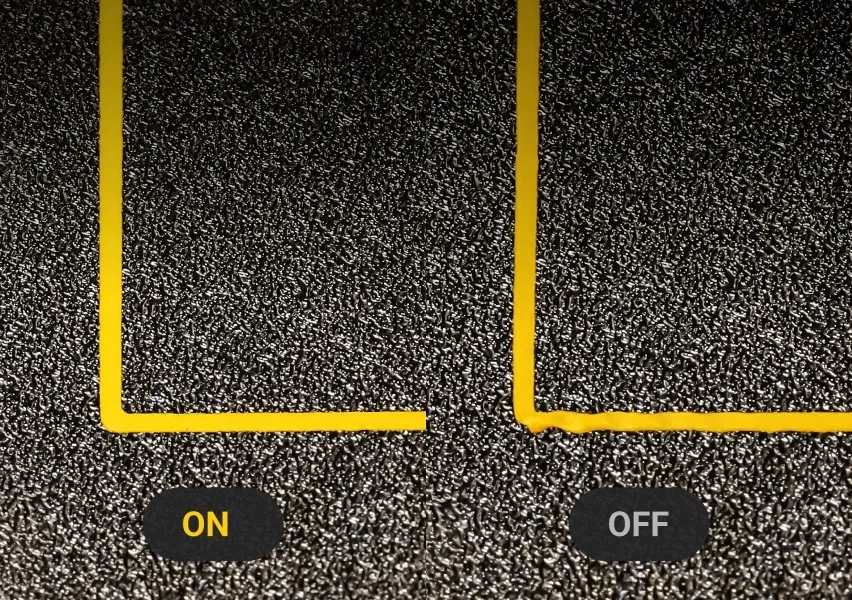

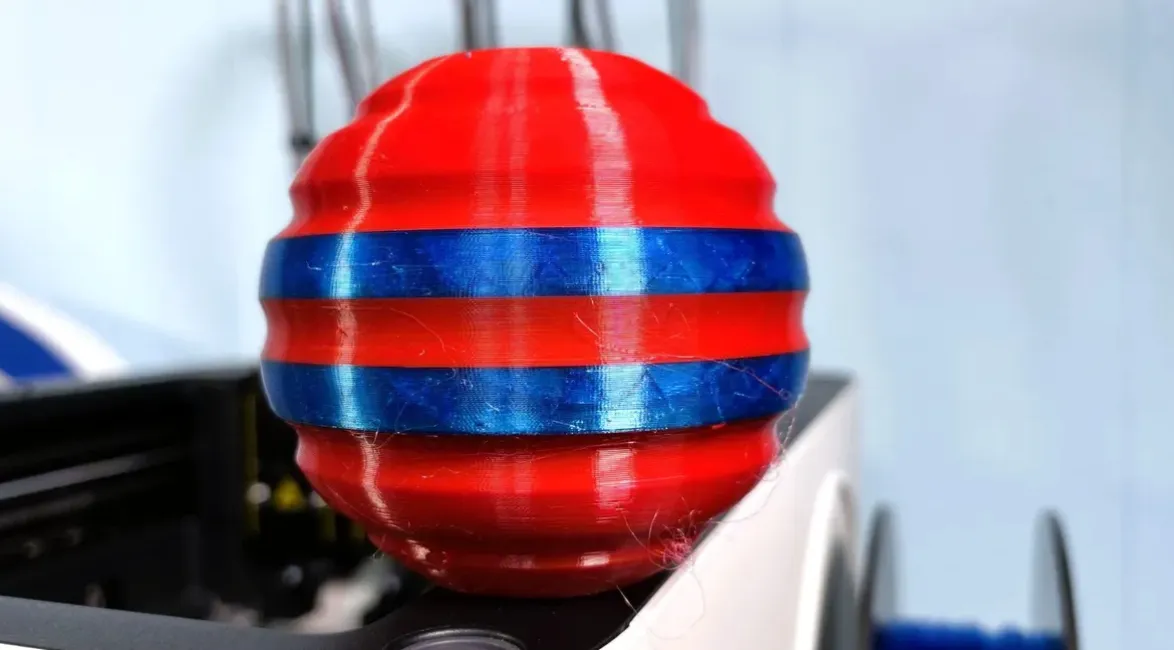

Vibration Compensation & Pressure Advance

Integrated vibration compensation reduces surface artifacts such as ghosting and ripples, while pressure advance ensures consistent extrusion flow during rapid speed and direction changes.

Fine-tuned Extrusion for Exquisite Details

The U1 uses Pressure Advance to stay ahead of flow delays, especially during quick moves or sharp corners. It tweaks extrusion timing based on motion changes, so filament flows smoothly even when speeds shift. That means fewer blobs, less thinning, and crisp, consistent detail.

The First Layer Matters Too

The automatic mesh bed leveling delivers a flat, grippy first layer, setting the stage for every print.

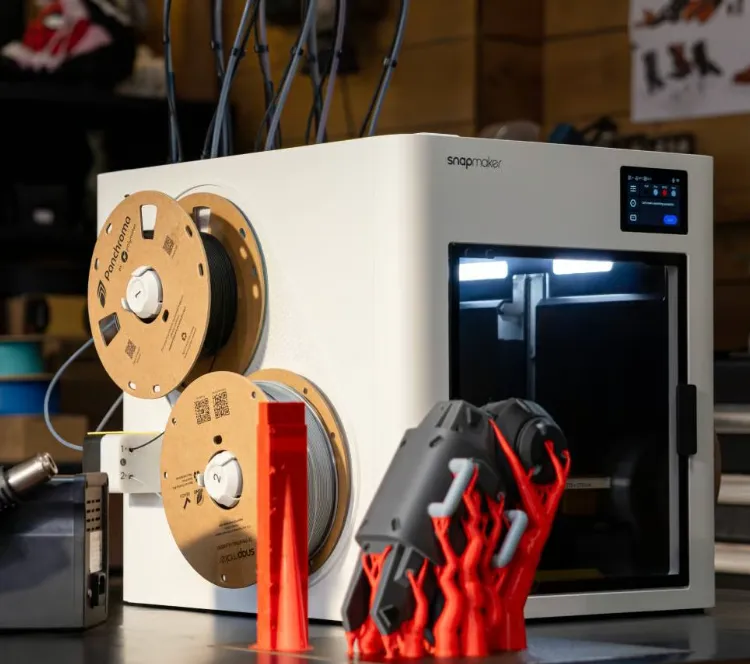

Effortless Filament Management

The U1 comes equipped with a super-compact automatic filament system that holds up to four spools on standby. It handles everything from filament detection and loading, so you can print in vivid color, hassle-free.

Auto-loading

No more threading, fiddling, or guesswork. Just hang your filament and let it roll.

Backup Mode

RFID Recognition

270 × 270 × 270 mm Build Volume

The U1 offers a 270 × 270 × 270 mm build area, providing sufficient workspace for functional parts, multi-color models, and creative design applications.

Rock-Solid & Precise Locks

The U1 uses steel-ball kinematic couplings to click each print heat into perfect position, then locks it securely—no screws, no magnets, no extra motors. Locked fast, rock solid, tested over 1,000,000 swaps with zero failures.

Manage Your Prints with Ease

Snapmaker Orca builds on Orca Slicer’s powerful engine and adds engineer-tested profiles for official materials and machine models. Paired with the Snapmaker App, you can start, monitor, and control your prints from anywhere—and even capture time-lapses videos to replay your creation in motion. Easy print management is right at your fingertips.

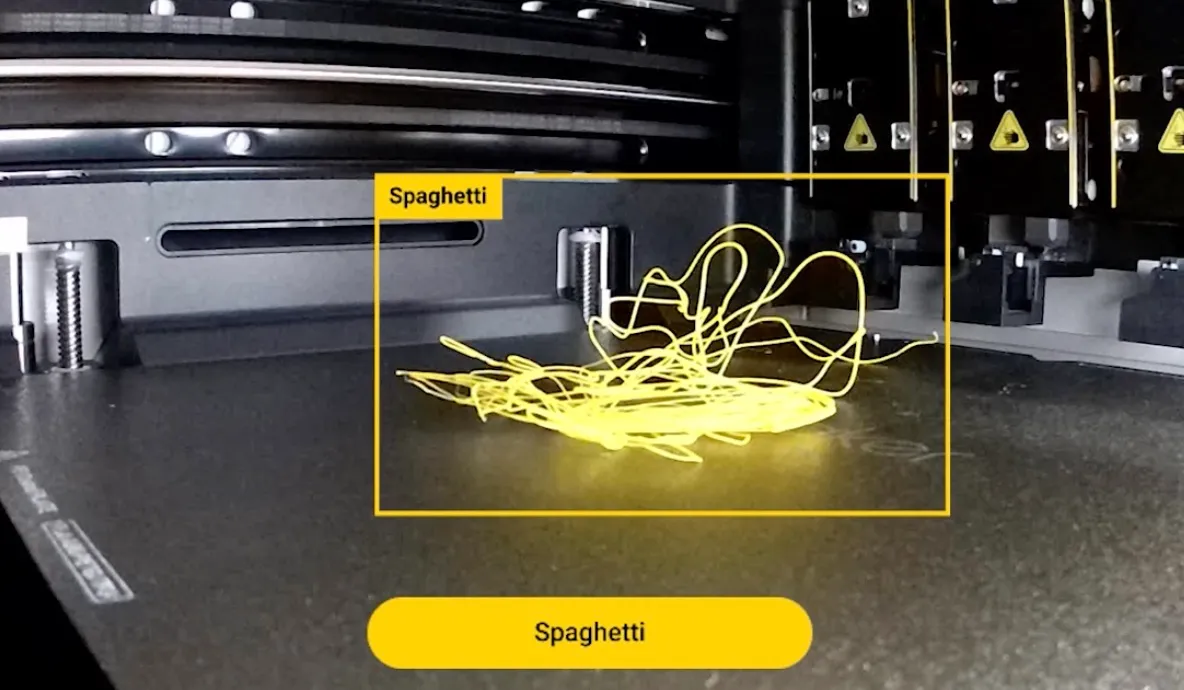

Anomaly Detection and Alert

Capture the Highlights, Skip the Messes

The built-in chamber camera isn’t just for time-lapses. Starting with an OTA firmware update planned for December 2025[6], its AI will detect spaghetti and workspace obstructions and alert you in Snapmaker Orca or the app, helping you avoid wasted time and material.

More Options

Downloads

Product videos

Snapmaker U1 Multi Material FDM 3D Printer

Snapmaker U1 Multi Material FDM 3D Printer

Reviews

There are no reviews yet