- High-speed printing TPU

- Soft, Flexible & Tough

- Outstanding Impact Resistance and Flexibility

- Includes High Temperature Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

- Color Code:51102

Looking for other products of Bambu LAB?

Description

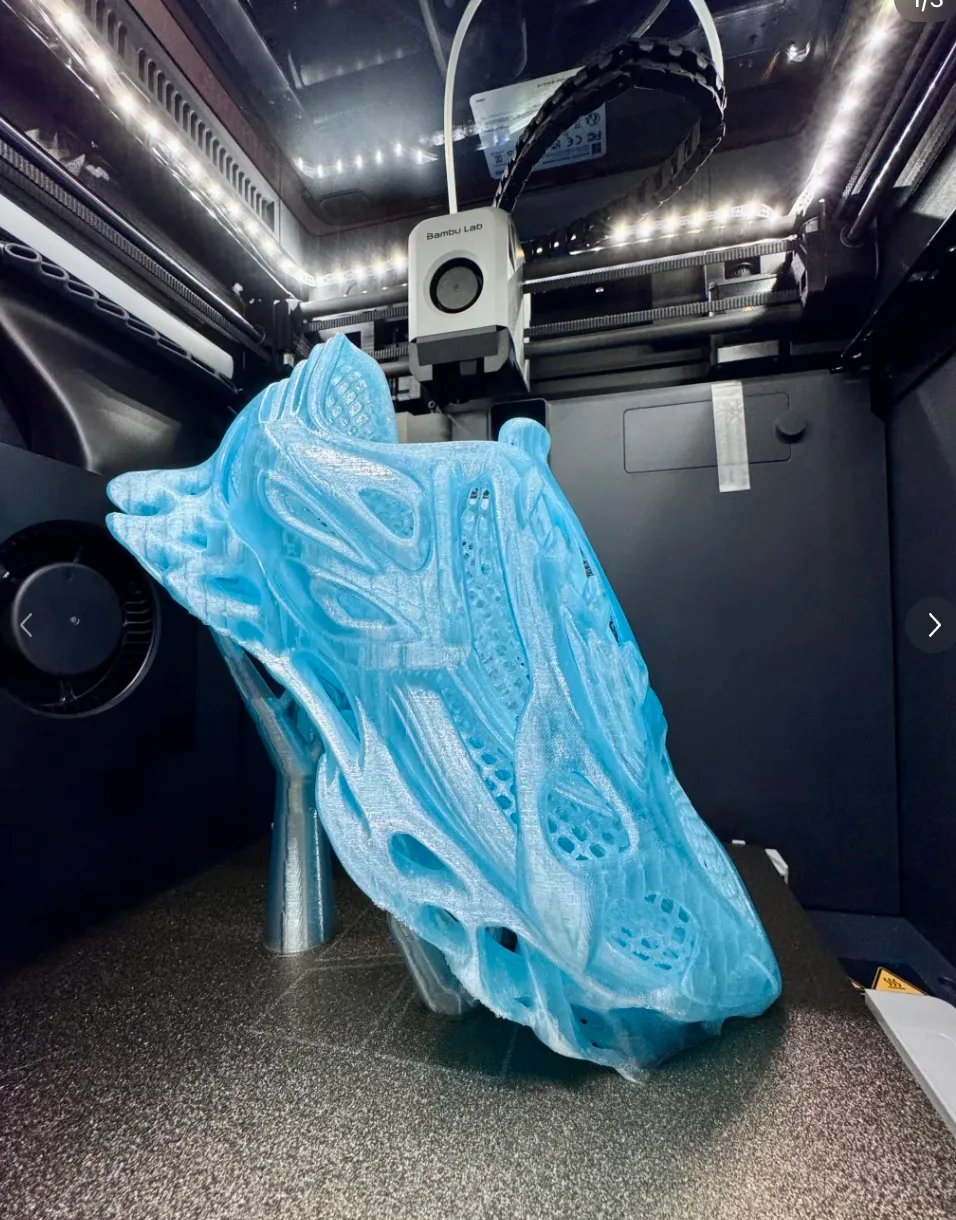

High-Speed Printing

Bambu TPU 95A HF is optimized for rapid 3D printing, offering speeds up to three times faster than standard TPU 95A. This allows you to complete prints significantly quicker without sacrificing quality or performance.

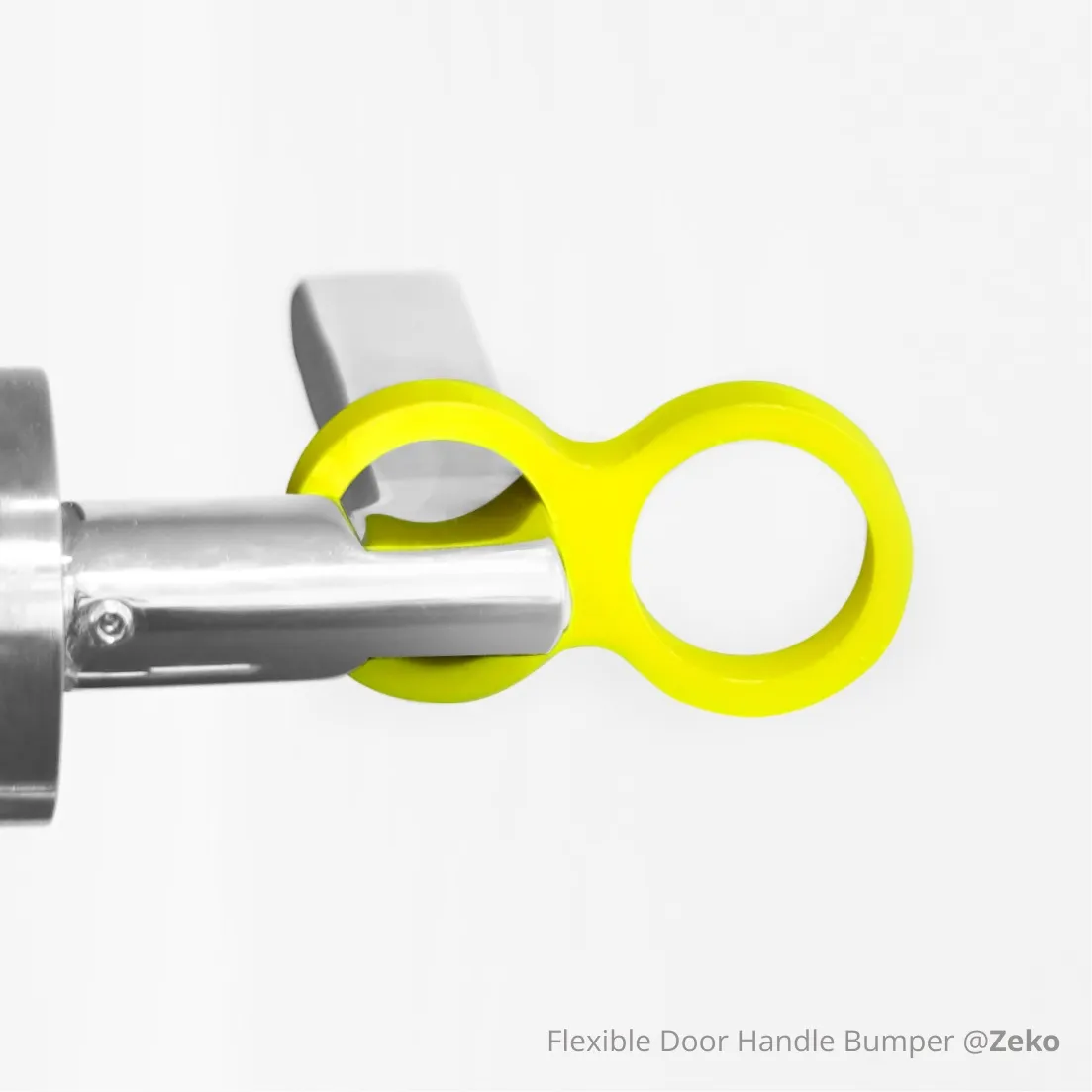

Soft, Flexible & Tough

Bambu TPU 95A HF combines softness, flexibility, and toughness, making it perfect for parts that require repeated bending, stretching, or impact resistance. Its durability ensures prints can endure everyday handling and challenging applications without breaking or deforming.

Exceptional Interlayer Adhesion

Despite its high-speed printing capability, TPU 95A HF ensures strong interlayer bonding. Your prints remain durable, resilient, and resistant to delamination, even under repeated stress or bending.

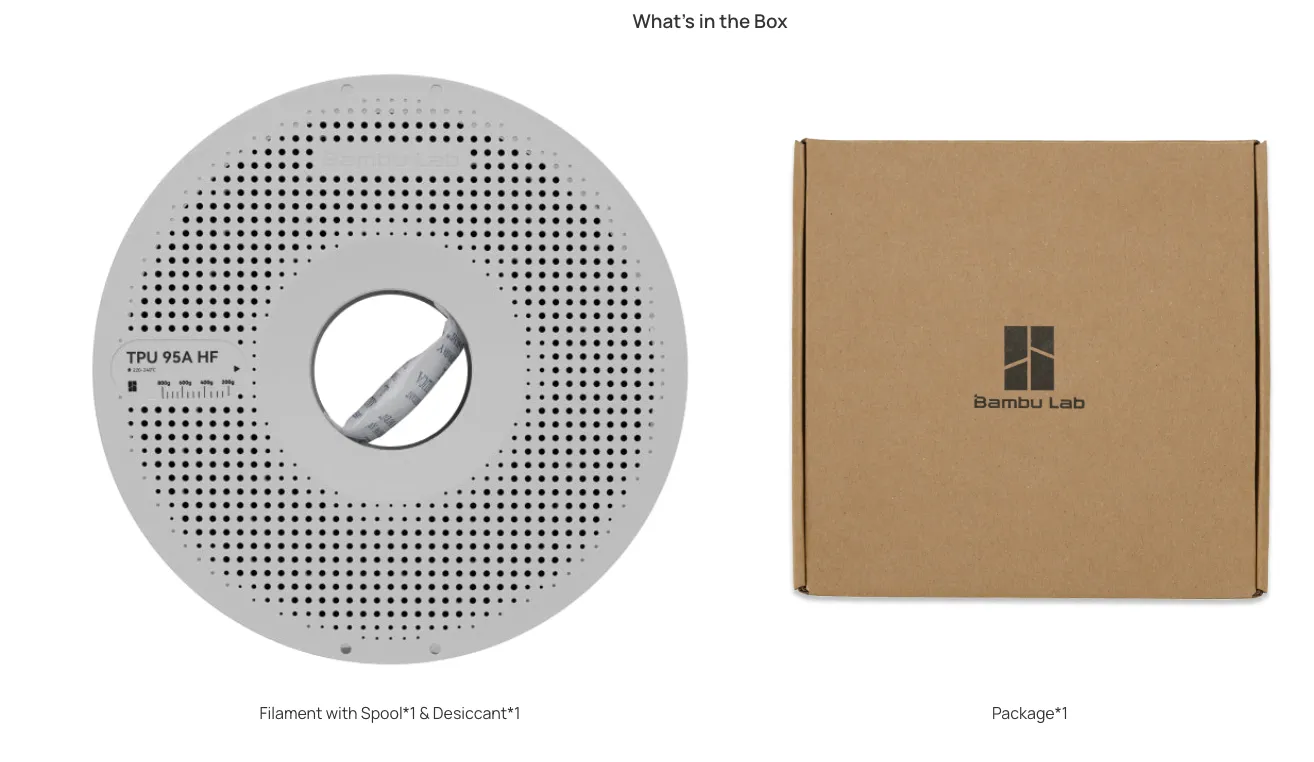

Includes High-Temperature Reusable Spool

The filament comes on a high-temperature reusable spool, allowing for convenient storage and prolonged filament life. This ensures your TPU 95A HF remains ready for consistent, high-quality prints.

Wholesale & Private Label Services

We offer wholesale and private label (OEM) services for a wide range of 3D printing accessories, including build plates, hotends, and related components.

More Options

Product videos

Printing Tips

- Dry out before use

- AMS & AMS lite NOT Compatible

- Drying conditions: 70℃ for 8 hrs. TPU 95A HF is highly sensitive to humidity. To achieve optimal printing performance, it is recommended further drying before use and after storage. For more details please refer to: Filament drying instructions on WIKI.

- To obtain higher printing quality, please check TPU Printing Guide before printing.

Specification

Recommended Printing Settings

| Recommended Printing Settings | Value |

|---|---|

| Drying Settings (Blast Drying Oven) | 70 °C, 8 h |

| Printing and Keeping Container’s Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 220 – 240 °C |

| Bed Temperature (with Glue) | 30 – 35 °C |

| Printing Speed | < 200 mm/s |

High Speed Printing

| Property | Bambu TPU 95A | Bambu TPU 95A HF |

|---|---|---|

| Nozzle Temperature / °C | 230 | 230 |

| Max Volumetric Speed / (mm³/s) | 3.6 | 12 |

| Printing Speed / (mm/s) | 44 | 147 |

| Model Specimens | Diameter: 50 mm, Height: 100 mm, Infill: 40% | |

Exceptional Thermal Resistance

| Property | Normal PA6-CF | PA6-CF | PAHT-CF |

|---|---|---|---|

| Composition | Nylon 6, carbon fiber | Nylon 6, carbon fiber | PA12 & other long-chain PA, carbon fiber |

| AMS Compatibility | NO | NO | YES |

| Dry Out Before Use | Required | Required | Required |

| Printing Speed | < 100 mm/s | < 100 mm/s | < 100 mm/s |

| Printer Type | Enclosure | Enclosure | Enclosure |

| Impact Strength – XY (Dry) | 35.7 kJ/m² | 40.3 kJ/m² | 57.5 kJ/m² |

| Impact Strength – XY (Wet) | 65.4 kJ/m² | 57.2 kJ/m² | 62.3 kJ/m² |

| Bending Strength – XY (Dry) | 141 MPa | 151 MPa | 125 MPa |

| Bending Strength – XY (Wet) | 67 MPa | 95 MPa | 115 MPa |

| Layer Strength – Z (Dry) | 72 MPa | 80 MPa | 61 MPa |

| Layer Strength – Z (Wet) | 31 MPa | 45 MPa | 49 MPa |

| Bending Modulus – XY (Dry) | 4870 MPa | 5460 MPa | 4230 MPa |

| Bending Modulus – XY (Wet) | 1890 MPa | 3560 MPa | 3640 MPa |

| Layer Adhesion – Z (Dry) | 11.6 kJ/m² | 15.5 kJ/m² | 13.3 kJ/m² |

| Heat Deflection Temp (0.45 MPa) | 177 ℃ | 186 ℃ | 194 ℃ |

| Water Absorption (25 ℃, 55% RH) | 3.80% | 2.35% | 0.88% |

Accessory Compatibility

| Recommended Printing Settings | Bambu TPU 95A | Bambu TPU 95A HF |

|---|---|---|

| Nozzle Temperature / °C | 230 | 230 |

| Max Volumetric Speed / (mm³/s) | 3.6 | 12 |

| Printing Speed / (mm/s) | 44 | 147 |

| Model Specimens | Diameter: 50 mm, Height: 100 mm, Infill: 40% | |

Physical & Mechanical Properties

| Property | Value |

|---|---|

| Density | 1.22 g/cm³ |

| Vicat Softening Temperature | N / A |

| Heat Deflection Temperature | N / A |

| Melting Temperature | 183 °C |

| Melt Index | 36.5 ± 2.6 g/10 min |

| Tensile Strength | 27.3 ± 0.8 MPa |

| Breaking Elongation Rate | > 650% |

| Bending Modulus | N / A |

| Bending Strength | N / A |

| Impact Strength | N / A |

Bambu Lab White TPU 95A HF Filament 1KG 1.75MM with Spool

Bambu Lab White TPU 95A HF Filament 1KG 1.75MM with Spool

Reviews

There are no reviews yet