- Below 50μm Motion Accuracy Against Inevitable Uncertainties

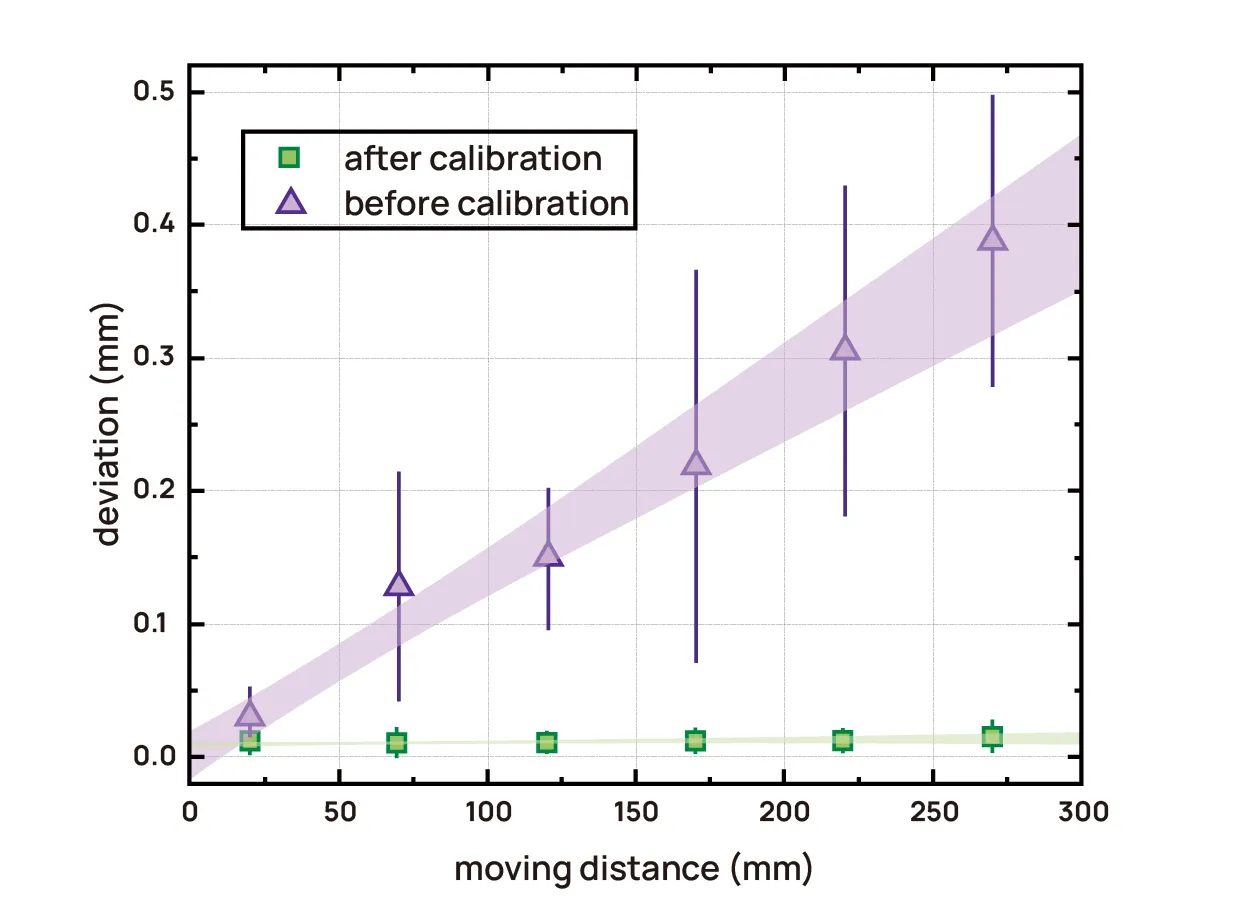

- The Larger the Print, the More Pronounced the Accuracy

- Achieve Injection-Molded-Level Quality

- 5-Minute Calibration for Weeks-Long Accuracy

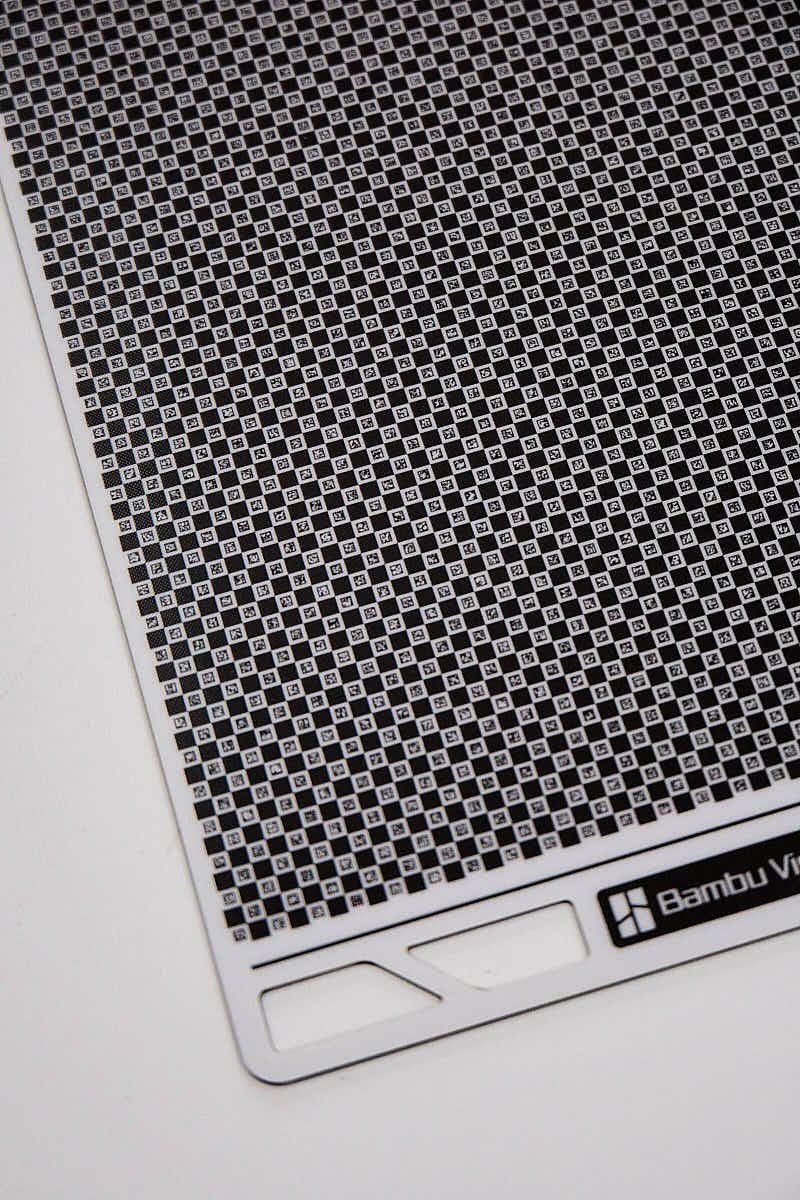

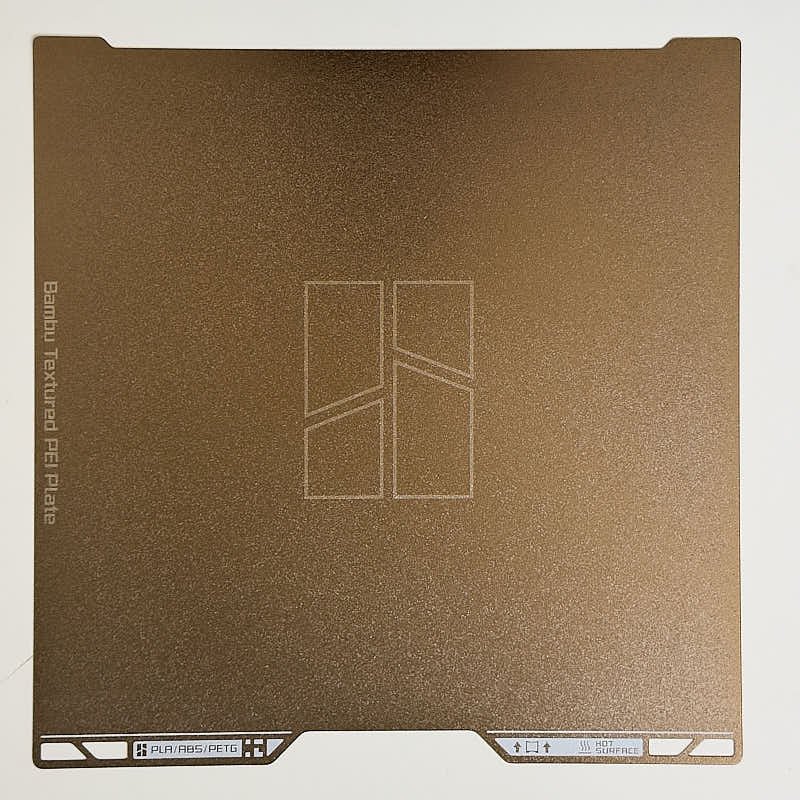

- Size:350*320mm

Looking for other products of Bambu Lab?

Specification

Key Printing Performance

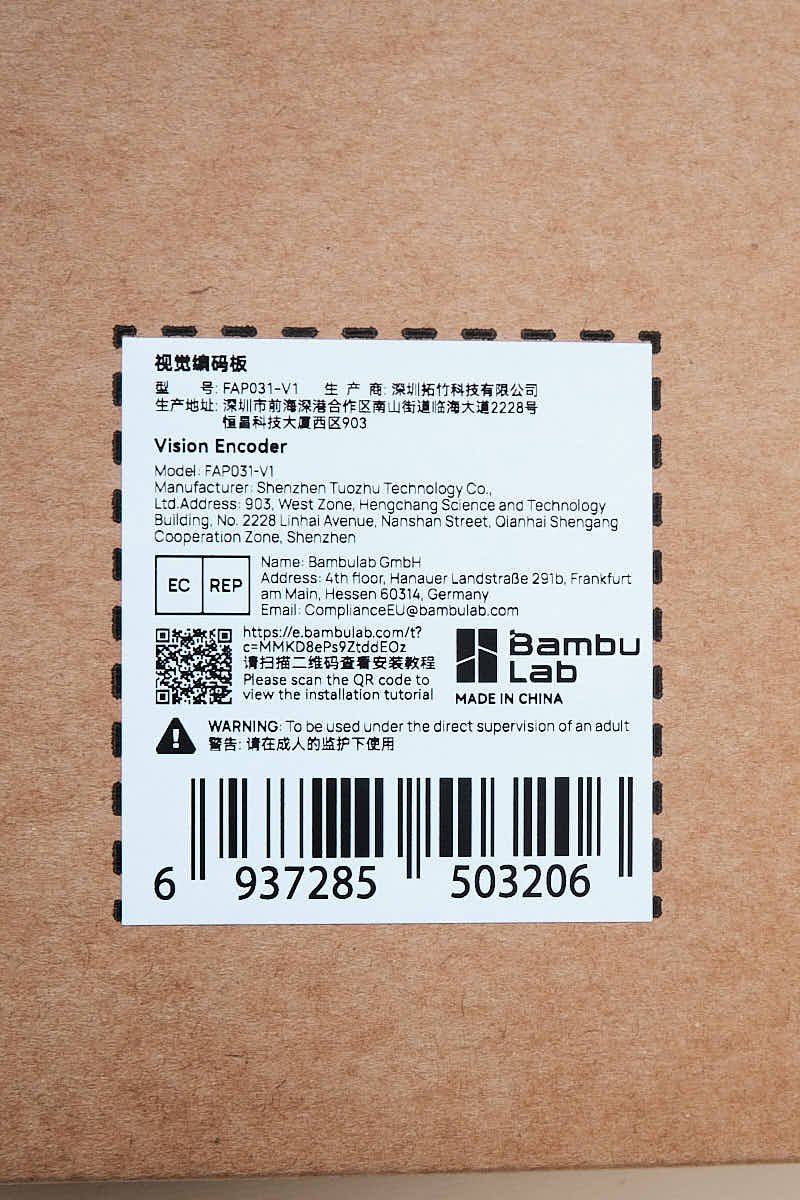

| Materials Metal, Plastic | Color Black, White | Packaging Size 393 × 380 × 15 mm |

| Packaging Weight 0.73 kg | Product Size |

Description

What’s in the Box?

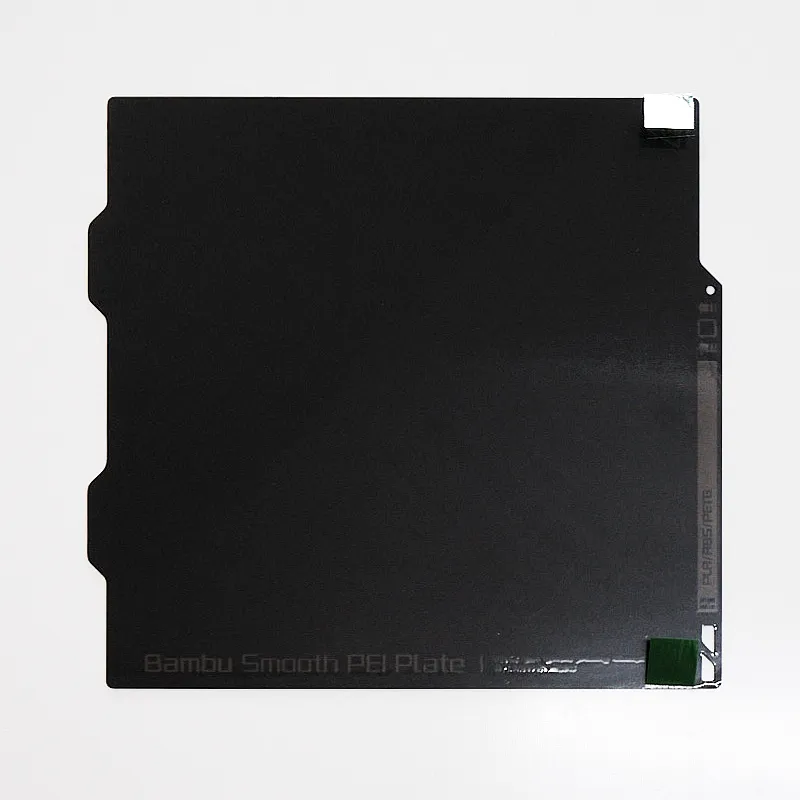

Vision Encoder *1

Ultra-Precise Motion Calibration

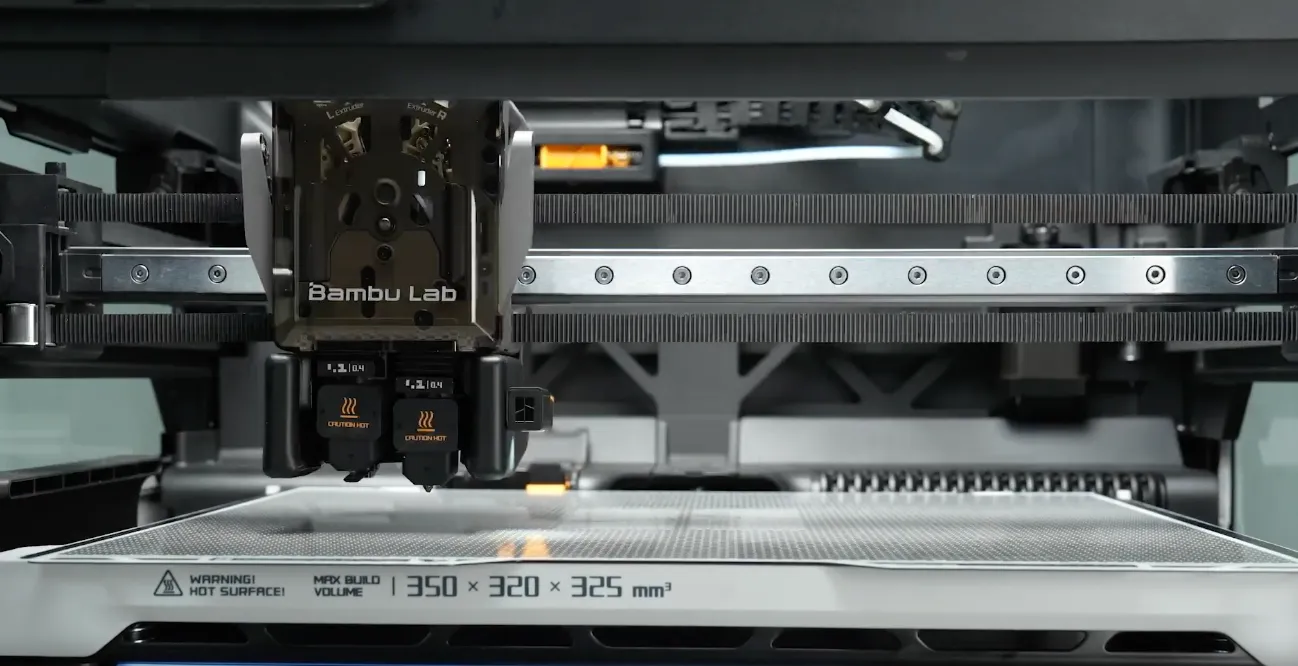

The Bambu Lab Vision Encoder is a next-generation calibration solution designed to dramatically improve motion accuracy on the H2 Series. By compensating for unavoidable mechanical tolerances and long-term wear, it achieves motion precision below 50μm, delivering consistently accurate results across machines and over time.

Sub-50μm Accuracy That Adapts Over Time

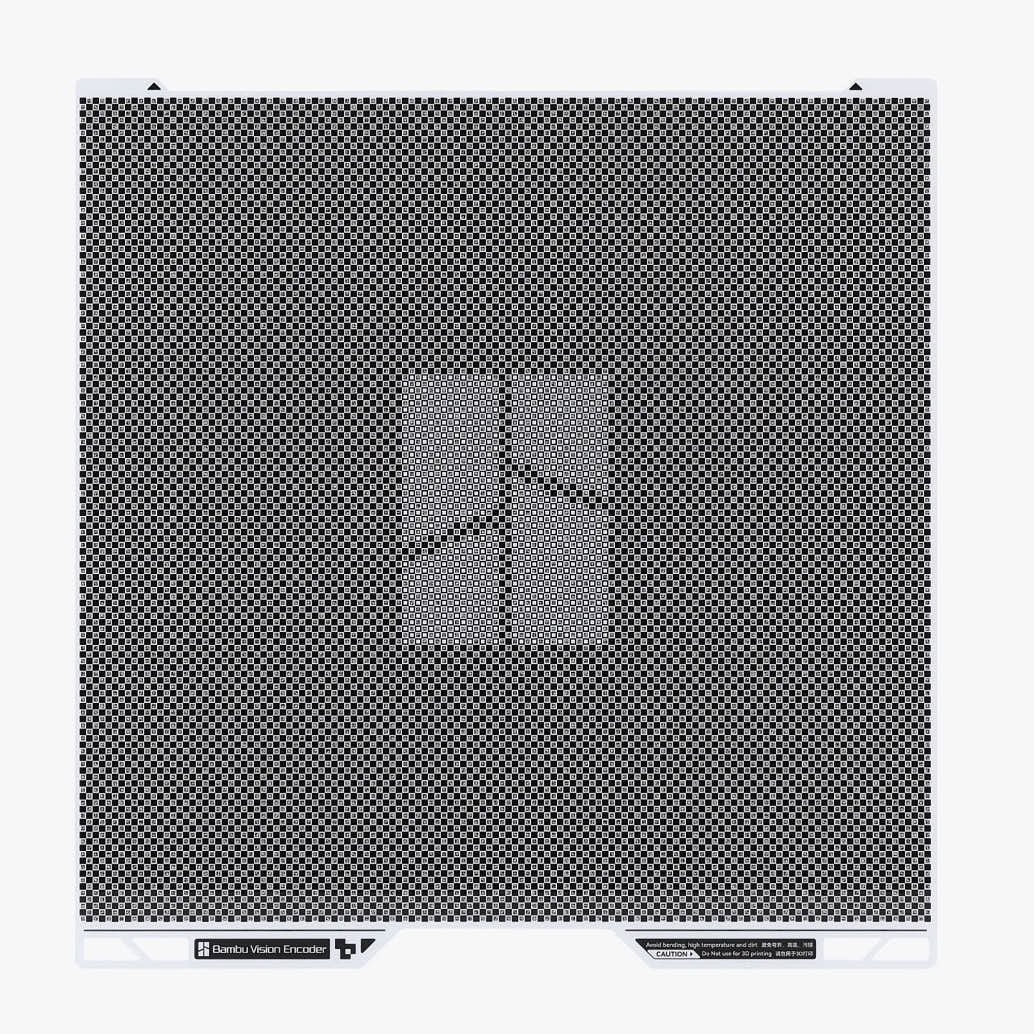

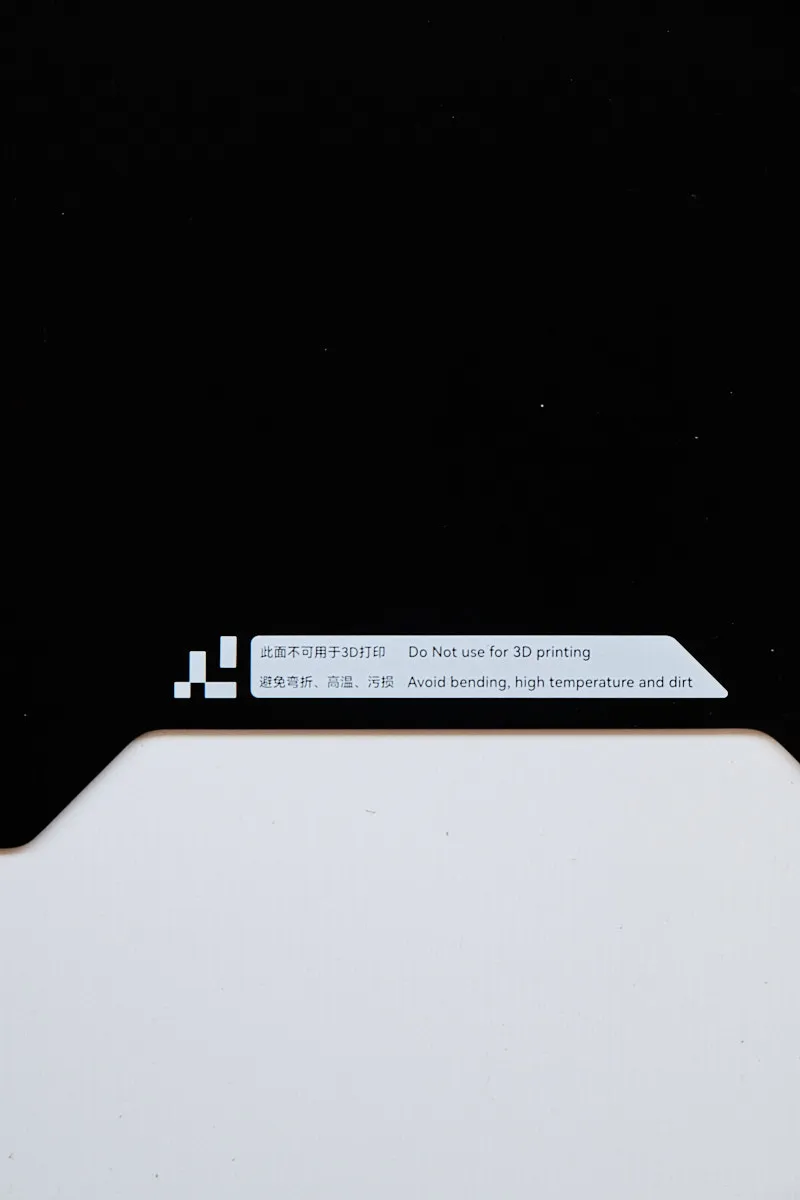

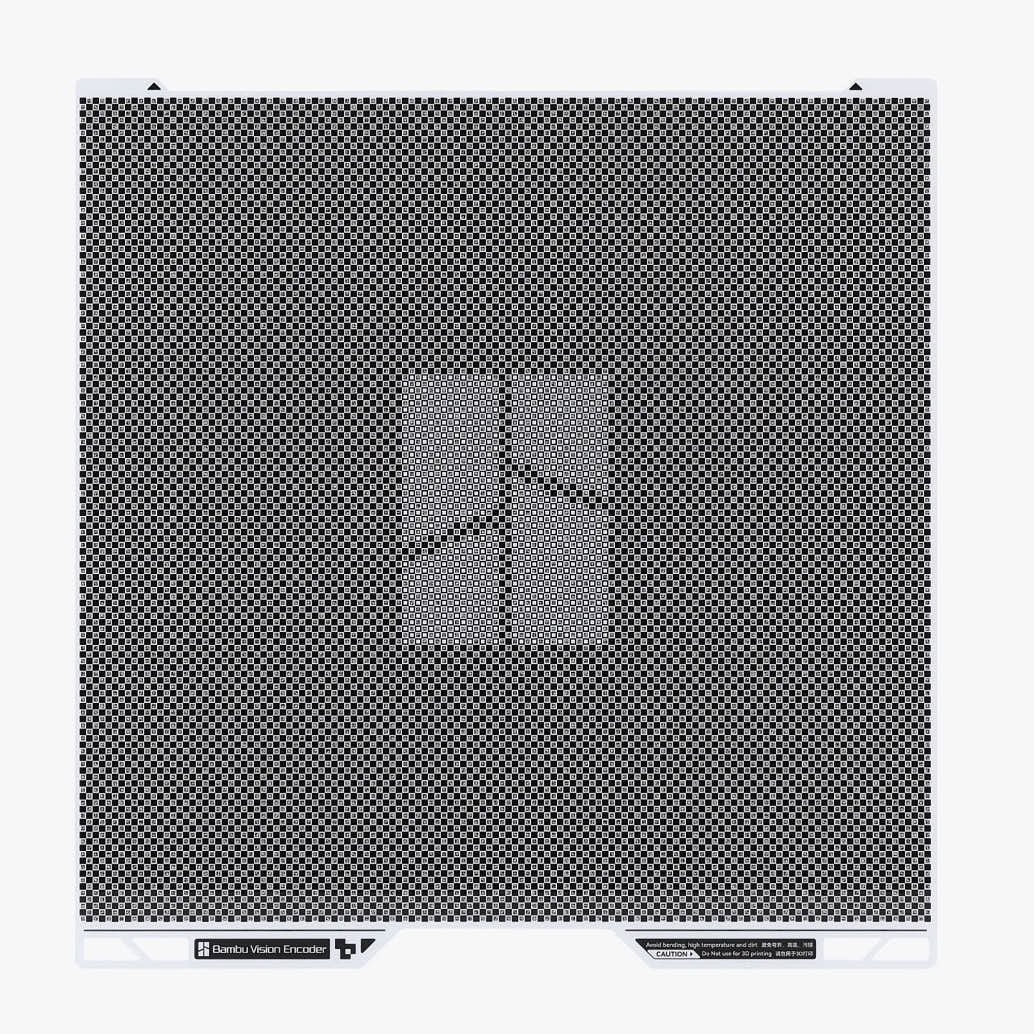

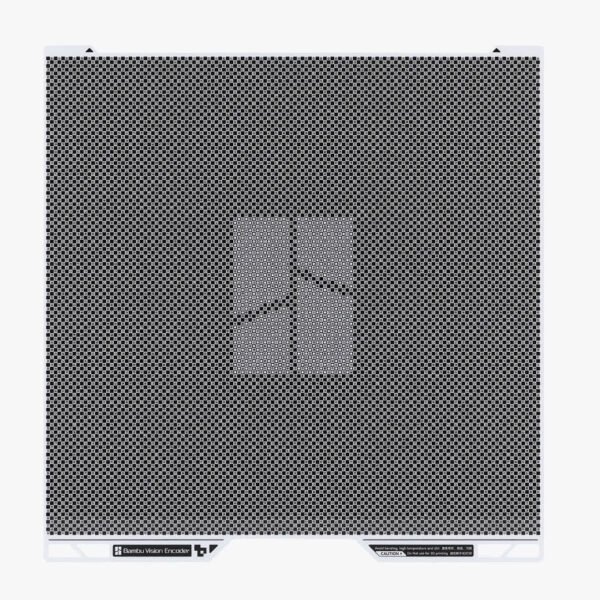

Equipped with a dense matrix of over 10,000 encoded markers and high-resolution optical measurement down to 5μm, the Vision Encoder precisely calibrates XY-axis motion. It continuously accounts for factors such as belt relaxation and mechanical aging, ensuring long-term dimensional reliability that stays thinner than a human hair.

Greater Prints, Greater Precision

Unlike traditional calibration methods, the Vision Encoder maintains accuracy independent of travel distance. As print size increases, its benefits become even more noticeable—making it especially suitable for large-format parts, architectural models, and functional components where dimensional accuracy is critical.

Injection-Molded-Level Fit and Finish

When combined with Bambu Studio’s Auto Hole-Contour Compensation, controlled chamber environment, and optimized filament profiles, the Vision Encoder enables parts with near injection-molded accuracy. Components fit together seamlessly, reducing post-processing and accelerating assembly workflows.

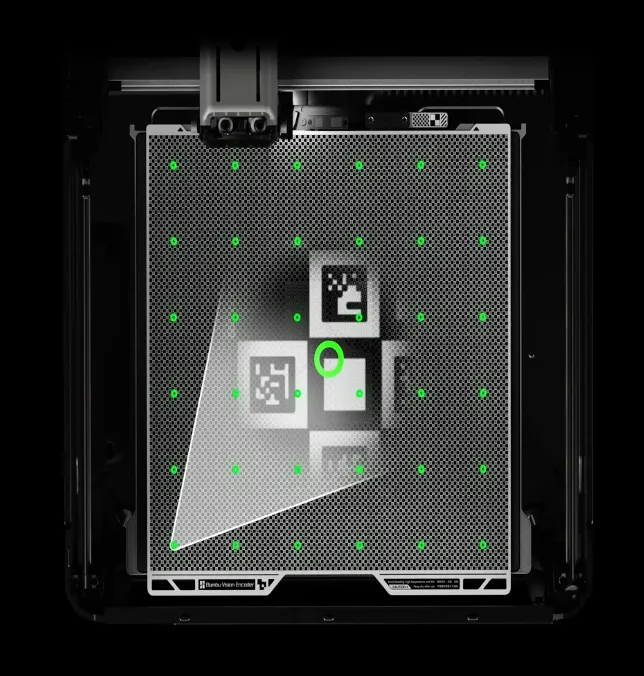

5-Minute Calibration for Weeks-Long Accuracy

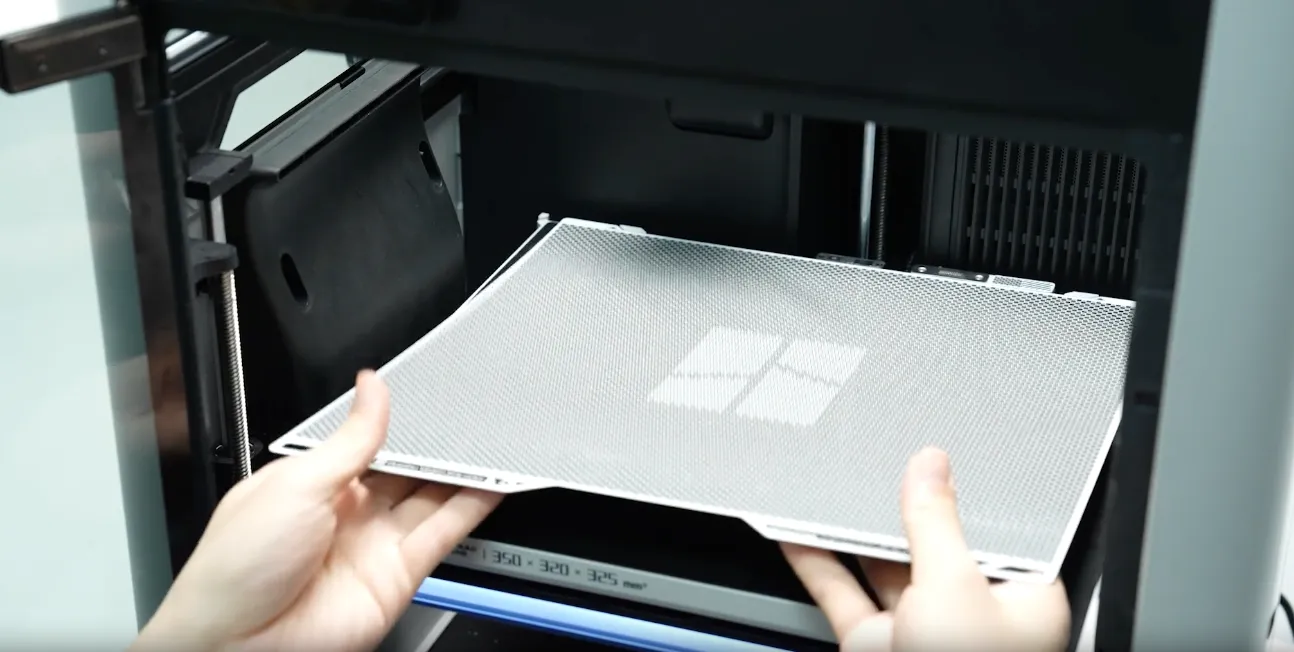

Place, calibrate, and go. A quick 5-minute calibration ensures weeks of ultra-high accuracy printing with no hassle. Just minutes of setup to counteract wear over time—keeping your prints precise and your workflow smooth. Absolutely worth it!

H2D / H2S Compatible Size

The 350 × 320 mm is fully compatible with the H2D and H2S printers

Wholesale & Private Label Services

We offer wholesale and private label (OEM) services for a wide range of 3D printing accessories, including build plates, hotends, and related components.

More Options

Usage Tips

Downloads

Product videos

Bambu Lab Vision Encoder Calibration Plate For H2D/H2S 3D Printer

Bambu Lab Vision Encoder Calibration Plate For H2D/H2S 3D Printer

Reviews

There are no reviews yet