- Ultra-High Heat Resistance

- Top-tier Flame Retardancy

- Peerless Mechanical Properties

- Solvent and Chemical Resistance

- Ultra-Low Water Absorption

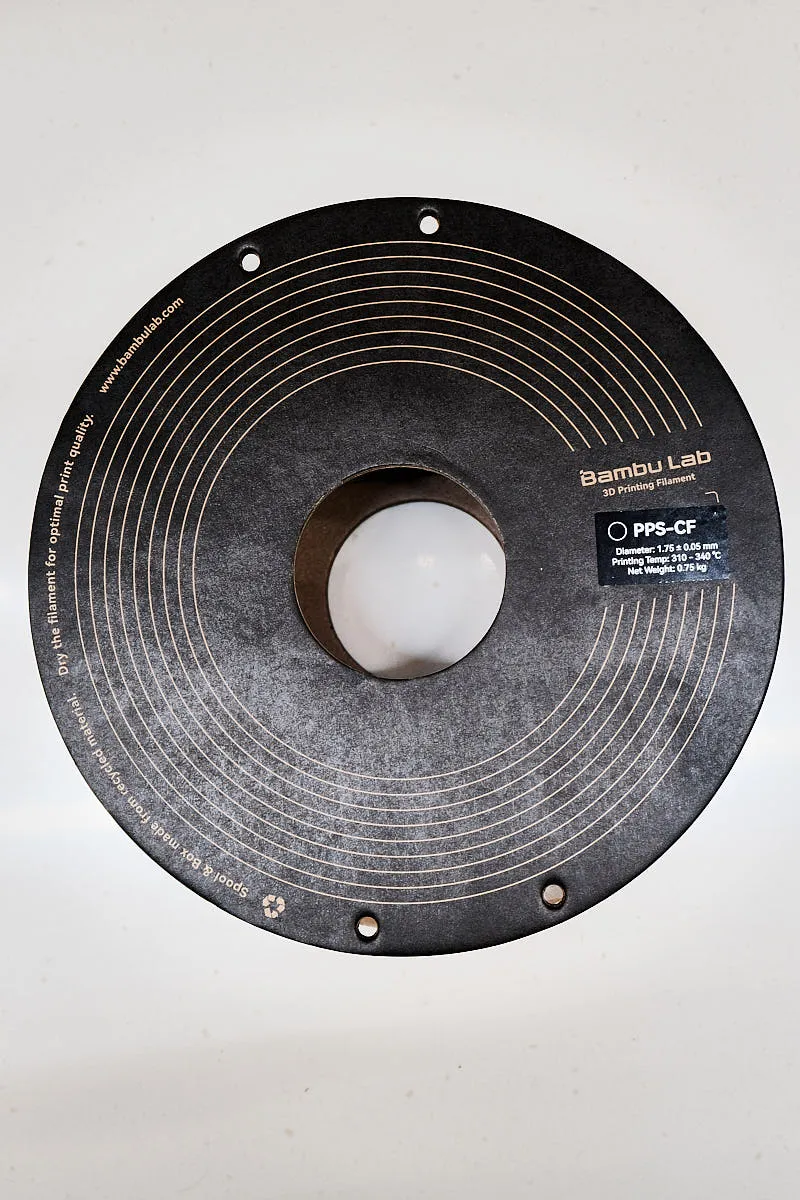

- Comes with Cardboard Spool

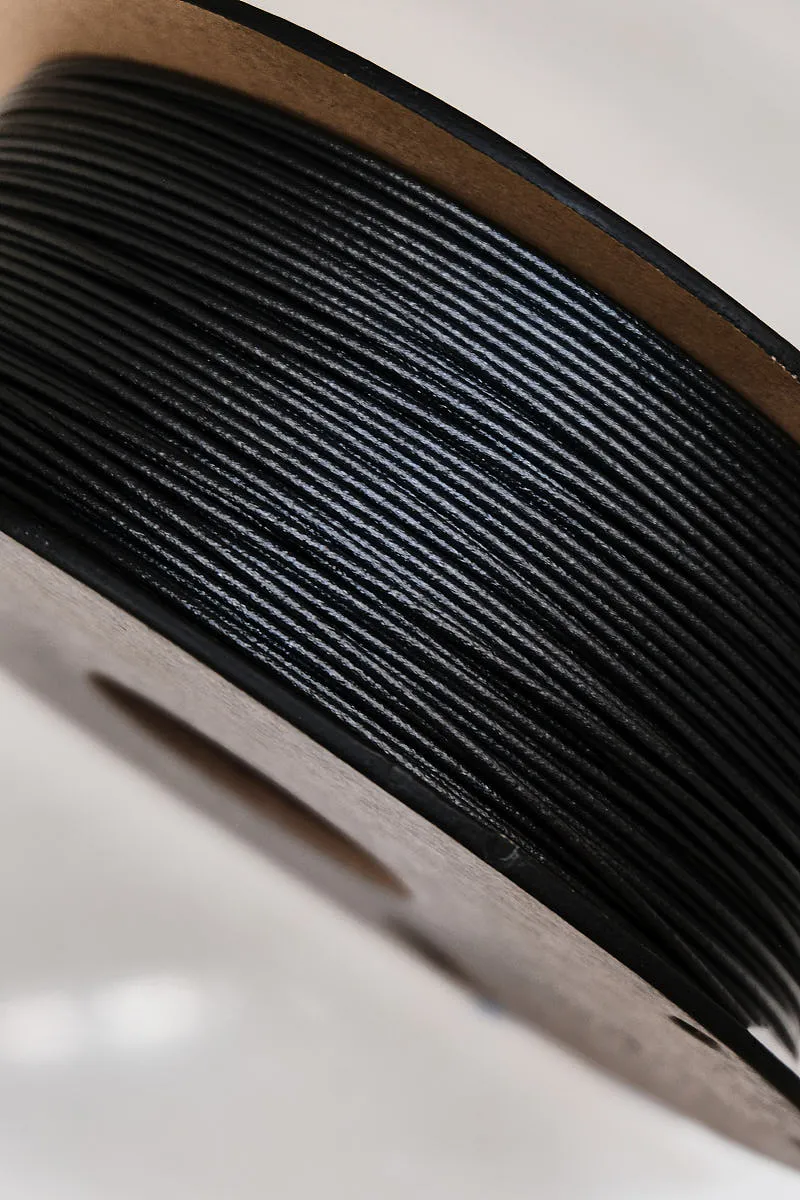

- Diameter: 1.75mm +/- 0.05mm

- For X1E/H2 Series Printing Only

- All AMS Series NOT Compatible

- 0.2 mm Nozzle NOT Compatible

- Stainless Steel Nozzle NOT Recommended

- Must Be Dried before Use to Achieve Optimal Print Quality

- Color Code: 76100

Looking for other products of Bambu LAB?

Description

Carbon Fiber-Reinforced Polyphenylene Sulfide Overview

Bambu PPS-CF is a high-performance composite material made from carbon fiber reinforced polyphenylene sulfide (PPS). By combining the inherent chemical stability and heat resistance of PPS resin with the strength and stiffness of carbon fiber, PPS-CF delivers exceptional mechanical performance, dimensional stability, and resistance to harsh environments, making it a specialized engineering plastic for demanding industrial applications.

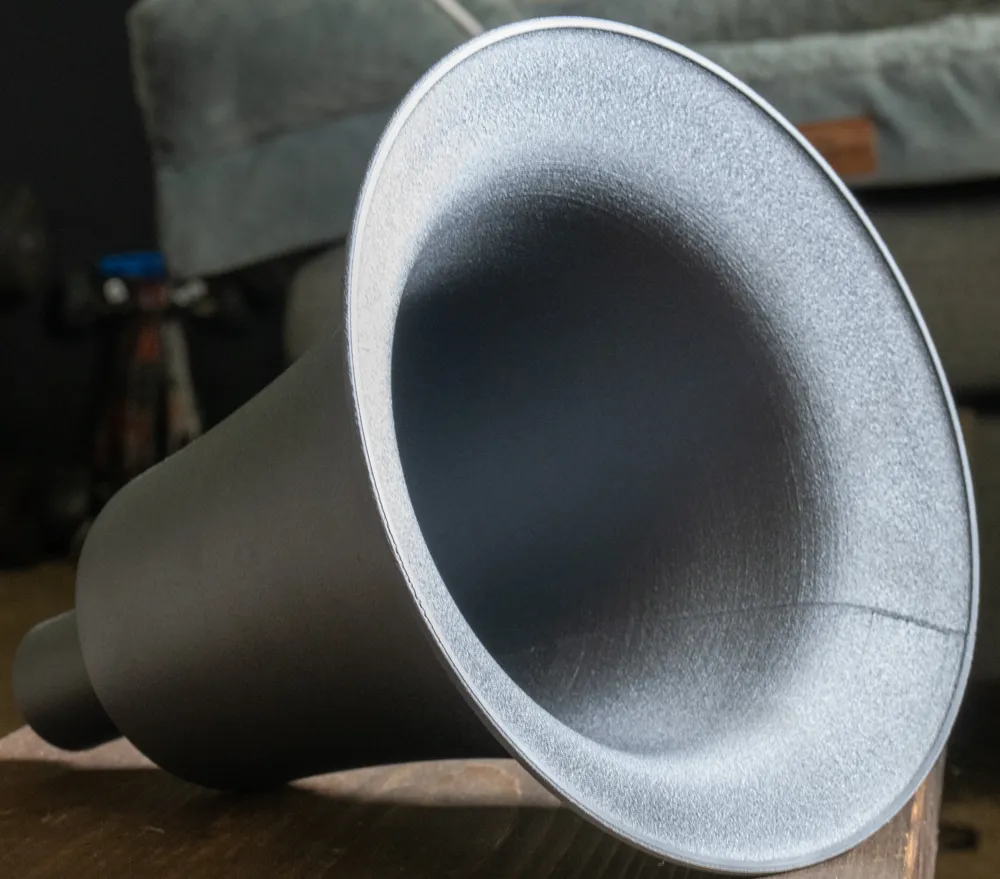

Unmatched Mechanical Properties

By integrating the rigidity of PPS polymers with carbon fiber reinforcement, Bambu PPS-CF delivers excellent stiffness, bending strength, and tensile strength. Its high dimensional stability and resistance to warping help large and complex prints maintain precision throughout the printing process, making it ideal for high-accuracy engineering components.

Solvent and Chemical Resistance

Bambu PPS-CF offers exceptional resistance to solvents and chemicals, second only to PTFE. It remains virtually insoluble in common solvents below 200°C and shows strong resistance to acids, bases, and salts, making it an excellent choice for chemically aggressive environments.

Ultra-Low Water Absorption

With an ultra-low moisture absorption rate of approximately 0.05%, Bambu PPS-CF maintains stable mechanical and thermal properties even in high-humidity conditions. Unlike traditional PA-CF materials that may soften or degrade when exposed to moisture, PPS-CF retains its strength and durability, ensuring consistent performance in moisture-sensitive applications.

Superior Flame Retardancy

Certified with a UL-94 V-0 flame retardant rating, Bambu PPS-CF provides exceptional fire resistance and safety. This makes it particularly suitable for applications in electronics, automotive, and industrial systems where flame resistance and long-term reliability are critical.

Wholesale & Private Label Services

We offer wholesale and private label (OEM) services for a wide range of 3D printing accessories, including build plates, hotends, and related components.

More Options

Printing Tips

Bambu PPS-CF Printing Guidelines:

- Nozzle Temperature: Recommended range is 310 to 340°C.

- Chamber Temperature: Recommended range is 60 to 90°C.

- Tip: Using higher values within these ranges can enhance the mechanical properties of the printed parts, especially in the Z-direction.

Drying Recommendations:

- Drying Temperature:

In a blast drying oven: 100°C to 140°C for 8 to 12 hours.

On an X1 printer’s heatbed: 110°C to 120°C for 10 to 12 hours (less effective than a blast drying oven).

- Important Note: Higher temperatures within the drying range yield better results, but do not exceed 160°C to avoid damaging the spool.

- Additional Information: For more details, refer to Printing tips for Engineering materials on WIKI.

Storage Tips:

- Storage Condition: To prevent the filament from absorbing moisture, use an airtight storage container with desiccant during printing.

- For Further Details: Please refer to Printing tips for Engineering materials on WIKI.

Annealing Prints:

- If you need to anneal the prints, please refer to the Technical Data Sheet (TDS) and the WIKI section Work After Printing Finished.

Specification

Heat Resistance Comparison

| Filament Type | PLA Basic | ABS | PC | PA-CF (Normal) | PA6-CF | PET-CF | PPA-CF | PPS-CF |

|---|---|---|---|---|---|---|---|---|

| Heat Deflection Temperature (0.45 MPa) | 57 °C | 87 °C | 117 °C | 184 °C | 186 °C | 205 °C | 227 °C | 264 °C |

Mechanical Properties Comparison

| Property | PET-CF | PPS-CF | Improved % |

|---|---|---|---|

| Stiffness (Bending Modulus – XY, Dry State) | 5320 MPa | 7160 MPa | 34.59% |

| Strength (Bending Strength – XY, Dry State) | 131 MPa | 142 MPa | 8.40% |

Parameters Comparison

| Parameter | PPS-CF | PET-CF | PA6-CF |

|---|---|---|---|

| Composition | Polyphenylene sulfide (PPS), Carbon Fiber | Polyethylene terephthalate (PET), Carbon Fiber | Nylon 6 (PA6), Carbon Fiber |

| AMS & AMS Lite Compatibility | Not Compatible | Not Compatible | Not Compatible |

| Dry Before Use | Required | Required | Required |

| Sealed During Printing | Sealed with desiccant | Sealed with desiccant | Sealed with desiccant |

| Printer Type | Enclosed | Enclosed (Recommended) / Open-frame | Enclosed |

| Nozzle | Hardened Steel 0.6 mm (Recommended) / 0.4 mm / 0.8 mm | Hardened Steel 0.6 mm (Recommended) / 0.4 mm / 0.8 mm | Hardened Steel 0.6 mm (Recommended) / 0.4 mm / 0.8 mm |

| Nozzle Temperature | 310 – 340 ℃ | 260 – 300 ℃ | 260 – 300 ℃ |

| Bed Temperature | 100 – 120 ℃ | 80 – 110 ℃ | 100 – 110 ℃ |

| Toughness (Impact Strength – XY, Dry) | 27.8 kJ/m² | 36.0 kJ/m² | 40.3 kJ/m² |

| Toughness (Impact Strength – XY, Wet) | 27.8 kJ/m² | 37.3 kJ/m² | 57.2 kJ/m² |

| Strength (Bending Strength – XY, Dry) | 142 MPa | 131 MPa | 151 MPa |

| Strength (Bending Strength – XY, Wet) | 142 MPa | 127 MPa | 95 MPa |

| Layer Strength (Bending Strength – Z, Dry) | 36 MPa | 49 MPa | 80 MPa |

| Layer Strength (Bending Strength – Z, Wet) | 36 MPa | 46 MPa | 45 MPa |

| Stiffness (Bending Modulus – XY, Dry) | 7160 MPa | 5320 MPa | 5460 MPa |

| Stiffness (Bending Modulus – XY, Wet) | 7160 MPa | 5240 MPa | 3560 MPa |

| Layer Adhesion (Impact Strength – Z, Dry) | 2.8 kJ/m² | 4.5 kJ/m² | 15.5 kJ/m² |

| Heat Resistance (HDT, 0.45 MPa, Dry) | 264 ℃ | 205 ℃ | 186 ℃ |

| Saturated Water Absorption Rate (25 °C, 55% RH) | 0.05% | 0.37% | 2.35% |

Recommended Printing Settings

| Recommended Printing Settings | Value |

|---|---|

| Drying Settings before Printing | 100 – 140 °C, 8 – 12 h |

| Printing and Keeping Container’s Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 310 – 340 °C |

| Bed Temperature (with Glue) | 100 – 120 °C |

| Printing Speed | < 100 mm/s |

Physical & Mechanical Properties

|

|

Bambu Lab PPS-CF Black Filament with Spool

Bambu Lab PPS-CF Black Filament with Spool

Reviews

There are no reviews yet