- Specialized for 3D RC Planes Printing

- Low Density and Light Weight

- Tough with Good Impact Resistance

- Matte Finish For Easy Coloring

- Diameter: 1.75mm +/- 0.03mm

- Recommended to dry out before use

- All AMS Series Compatible

- Color Code:14102

Looking for other products of Bambu Lab?

Description

Low Density & Lightweight Structure

Bambu PLA Aero achieves low density and lightweight prints through controlled foaming at high temperatures, creating fine internal pores within the model. This makes it an ideal material for energy-saving applications such as UAVs, aerodynamic models, and gliders.

Designed for Lightweight & Energy-Saving Prints

Although the filament density of Bambu PLA Aero is similar to regular PLA, the density of printed parts is reduced to approximately 50%–80%. When printing models of the same volume, PLA Aero parts can weigh about half as much as those made with PLA Basic.

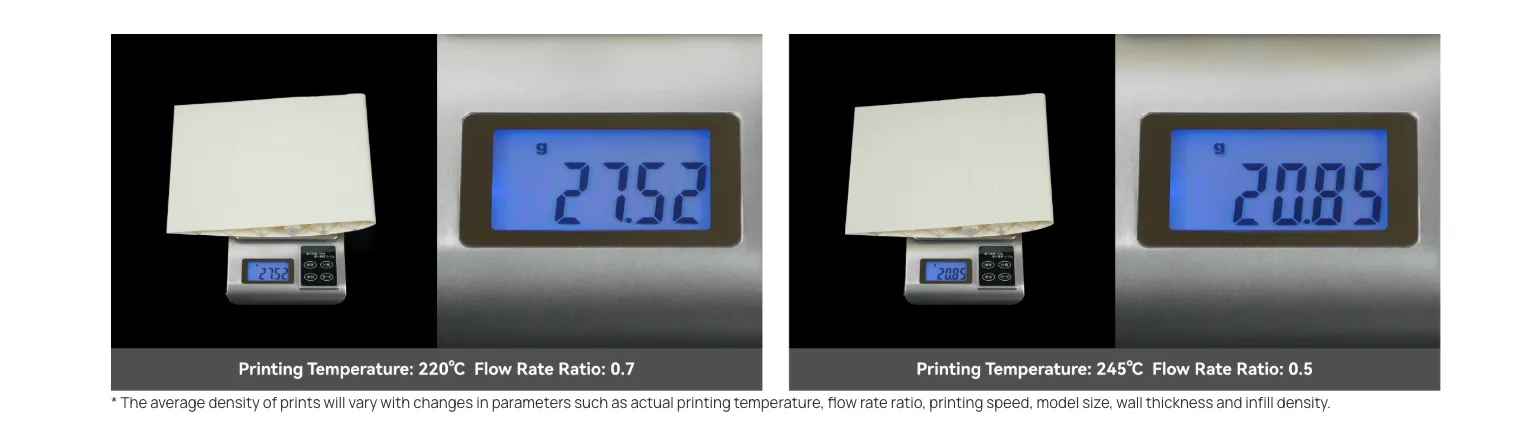

Controllable Print Density

The density of PLA Aero prints can be adjusted by increasing printing temperature and reducing flow rate. Actual print density varies depending on parameters such as temperature, flow ratio, printing speed, model size, wall thickness, and infill density, offering flexible control for different applications.

The relationship between Parameter Change and Density

| Parameter Setting | Parameter Change | Average Density |

|---|---|---|

| Printing Temperature | Increases ↗ | Decreases ↘ |

| Printing Speed | Increases ↗ | Stable or Increases ↗ |

| Flow Rate Ratio | Increases ↗ | Increases ↗ |

| Model Size | Increases ↗ | Decreases ↘ |

| Wall Thickness (Wall Loops) | Increases ↗ | Increases ↗ |

| Infill Density | Increases ↗ | Increases ↗ |

The relationship between the maximum foaming rate, minimum print density, and printing temperature of PLA Aero.

| Printing Temperature | Minimum Flow Rate Ratio | Maximum Volumetric Expansion Ratio | Maximum Foaming Rate | Minimum Prints Density |

|---|---|---|---|---|

| 190 °C | ~ 0.95 | ~ 100% | ~ 0% | ~ 1.17 g/cm³ |

| 200 °C | 0.89 | 110% | 10% | 1.06 g/cm³ |

| 210 °C | 0.85 | 115% | 15% | 1.02 g/cm³ |

| 220 °C | 0.76 | 129% | 29% | 0.91 g/cm³ |

| 230 °C | 0.62 | 158% | 58% | 0.74 g/cm³ |

| 240 °C | 0.45 | 217% | 117% | 0.54 g/cm³ |

| 250 °C | 0.38 | 258% | 158% | 0.45 g/cm³ |

| 260 °C | 0.35 | 280% | 180% | 0.42 g/cm³ |

| 270 °C | 0.37 | 265% | 165% | 0.44 g/cm³ |

Nozzle Type: 0.4 mm

Printing Speed: 80 mm/s

Model Size (L × W × H): 80 × 10 × 4 mm³ (XY direction)

Note: The actual required flow rate ratio and final print density may vary depending on model geometry, wall thickness, infill density, and printing parameters.

Tough with Good Impact Resistance

Compared to pre-foaming Wood PLA, Bambu PLA Aero produces tougher prints with improved resistance to impact, collision, and accidental drops, making it suitable for functional lightweight parts.

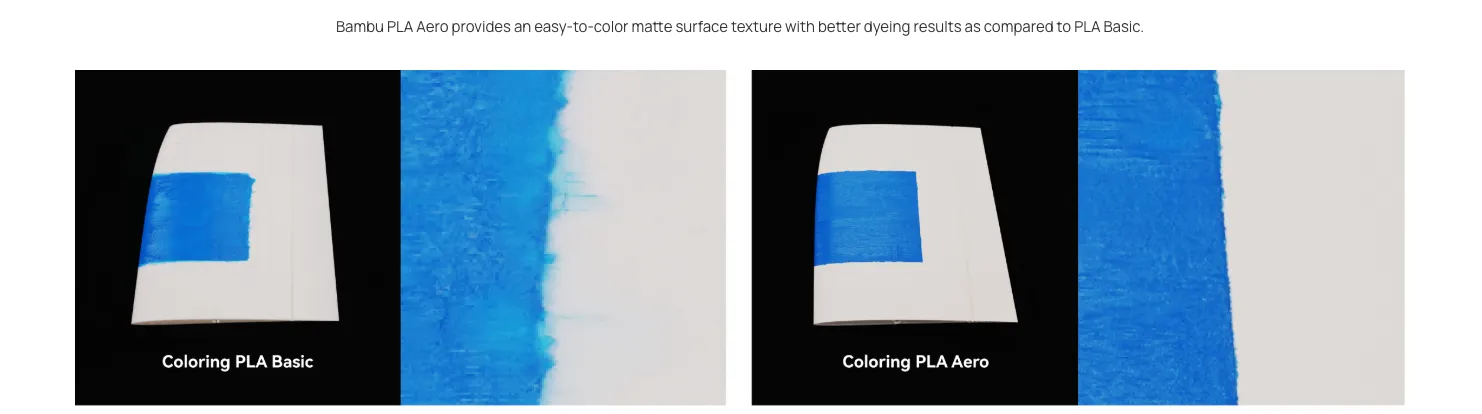

Matte Finish for Easy Coloring

Bambu PLA Aero features a matte surface texture that is easy to color and dye. Compared to PLA Basic, the matte finish delivers better dye absorption and more even coloring results, ideal for customized and painted models.

Important Printing Notes for PLA Aero

Foaming PLA materials such as Bambu PLA Aero require strict material drying and precise parameter control. Please carefully review the printing instructions for aircraft models using foaming PLA before starting the printing process to ensure stable foaming behavior and consistent results.

Wholesale & Private Label Services

We offer wholesale and private label (OEM) services for a wide range of 3D printing accessories, including build plates, hotends, and related components.

More Options

Product videos

Printing Tips

• PLA Aero filament is relatively soft which may result in material loading and unloading failures during AMS printing.

• Drying conditions: 55℃ for 8 hrs. PLA Aero is highly sensitive to humidity. To achieve optimal printing performance, it is recommended further drying before use and after storage. For more details please refer to: Filament drying instructions on WIKI.

Specification

Accessory Compatibility

| Accessory Compatibility | Specification |

|---|---|

| Build Plate | Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate |

| Hotend |

Hotend with Hardened Steel Nozzle 0.4 mm Hotend with Stainless Steel Nozzle 0.4 mm Hotend with Hardened Steel Nozzle 0.6 mm / 0.8 mm Hotend with Stainless Steel Nozzle 0.2 mm |

| Adhesive | Bambu Liquid Glue, Glue Stick |

Parameters Comparison

| Specification | PLA Basic | PLA Aero |

|---|---|---|

| Printing Temperature | 190 – 230 ℃ | 220 – 260 ℃ |

| Printing Speed | < 300 mm/s | < 180 mm/s |

| Flow Rate Ratio | 0.96 – 1.00 | 0.50 – 0.80 |

| Filament Density | 1.24 g/cm³ | 1.21 g/cm³ |

| Foaming Rate | / | 0 – 120% |

| Prints Density | 1.21 g/cm³ | 0.55 – 1.05 g/cm³ |

Recommended Printing Settings

| Recommended Printing Settings | Specification |

|---|---|

| Drying Settings (Blast Drying Oven) | 55 °C, 8 h |

| Printing & Storage Humidity | < 20% RH (Sealed, with desiccant) |

| Nozzle Temperature | 220 – 260 °C |

| Bed Temperature (with Glue) | 35 – 45 °C |

| Printing Speed | < 180 mm/s |

Physical Properties

| Physical Properties | Value |

|---|---|

| Density | 1.21 g/cm³ |

| Vicat Softening Temperature | 54 °C |

| Heat Deflection Temperature | 53 °C |

| Melting Temperature | 153 °C |

| Melt Index | 7.7 ± 0.6 g/10 min |

Mechanical Properties

| Mechanical Properties | Value |

|---|---|

| Tensile Strength | 24 ± 2 MPa |

| Breaking Elongation Rate | 2.6 ± 0.7 % |

| Bending Modulus | 1690 ± 120 MPa |

| Bending Strength | 45 ± 4 MPa |

| Impact Strength | 28.8 ± 1.3 kJ/m² |

Bambu Lab PLA Aero White Filament with Spool

Bambu Lab PLA Aero White Filament with Spool

Reviews

There are no reviews yet