- Very Low Moisture Absorption

- Exceptional Mechanical Properties

- High-Dimensional Stability

- Exceptional Thermal Resistance

- Comes with High Temperature Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

- 0.2 mm Nozzle NOT Compatible

- Stainless Steel Nozzle NOT Recommended

- All AMS Series NOT Compatible

- Dry before Use for the Highest Print Quality

- Color Code: 71100

Looking for other products of Bambu Lab?

Description

Bambu PET-CF Overview

Bambu PET-CF is a composite material made from tough PET resin reinforced with carbon fiber. The addition of carbon fiber significantly enhances hardness and mechanical strength while preserving the low warping and low shrinkage characteristics of standard PET. With excellent heat resistance, dimensional stability, and low moisture absorption, Bambu PET-CF is well suited for load-bearing structures and parts used in high-temperature or high-humidity environments. Its surface finish also features a subtle, soft glow appearance.

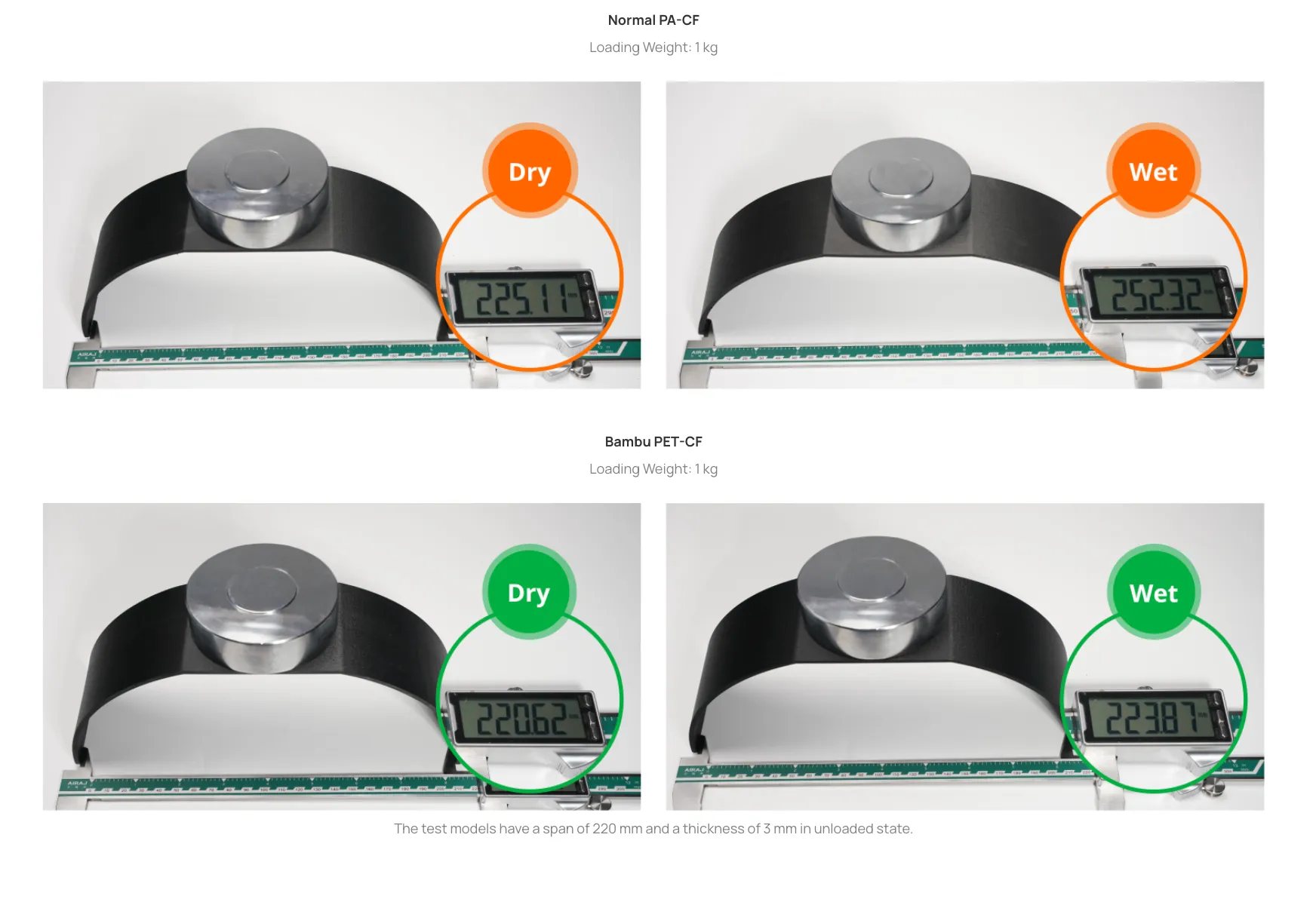

Low Moisture Absorption

Under saturated water absorption conditions, Bambu PET-CF exhibits minimal loss in strength and stiffness. This stability makes it a reliable material choice for printed parts that are exposed to humid or moisture-rich environments.

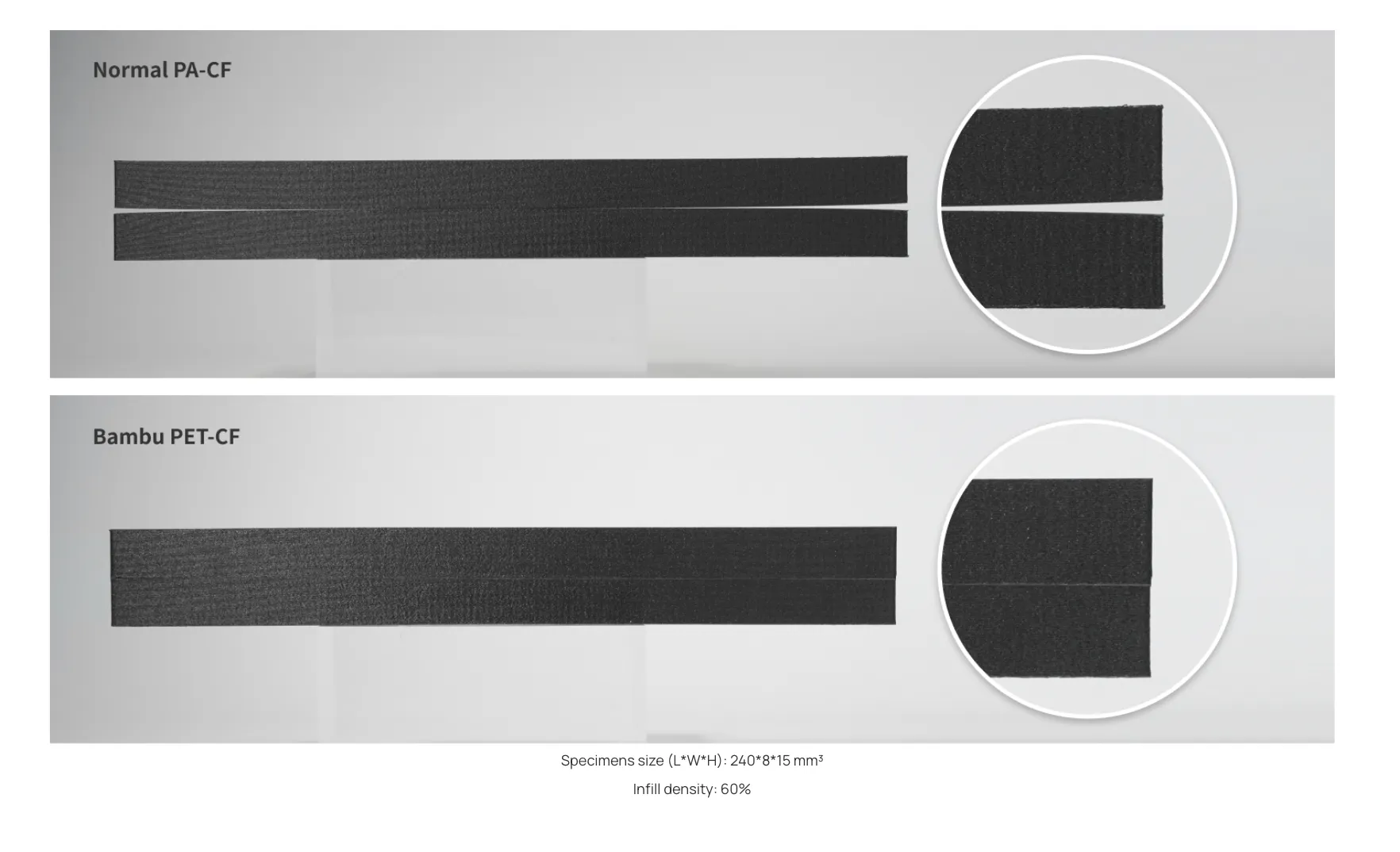

High Dimensional Stability

Thanks to its strong resistance to creep and warping, Bambu PET-CF maintains excellent dimensional accuracy after printing. Parts produced with this material can achieve precise fitting and consistent geometry, even in demanding structural applications.

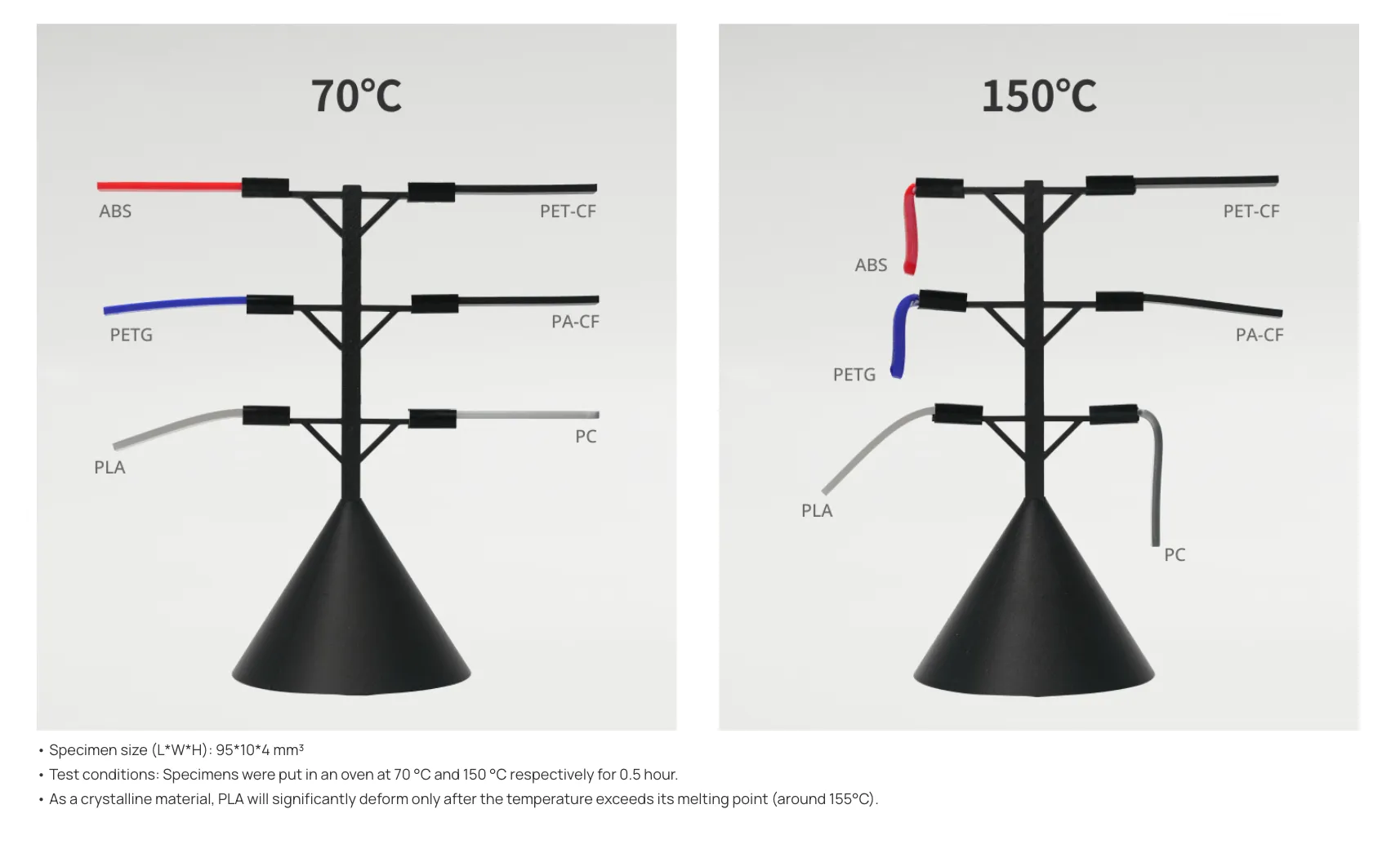

Exceptional Thermal Resistance

Bambu PET-CF offers excellent thermal resistance, allowing printed parts to retain strength and shape when exposed to elevated temperatures. This makes it suitable for applications where both mechanical performance and heat stability are required.

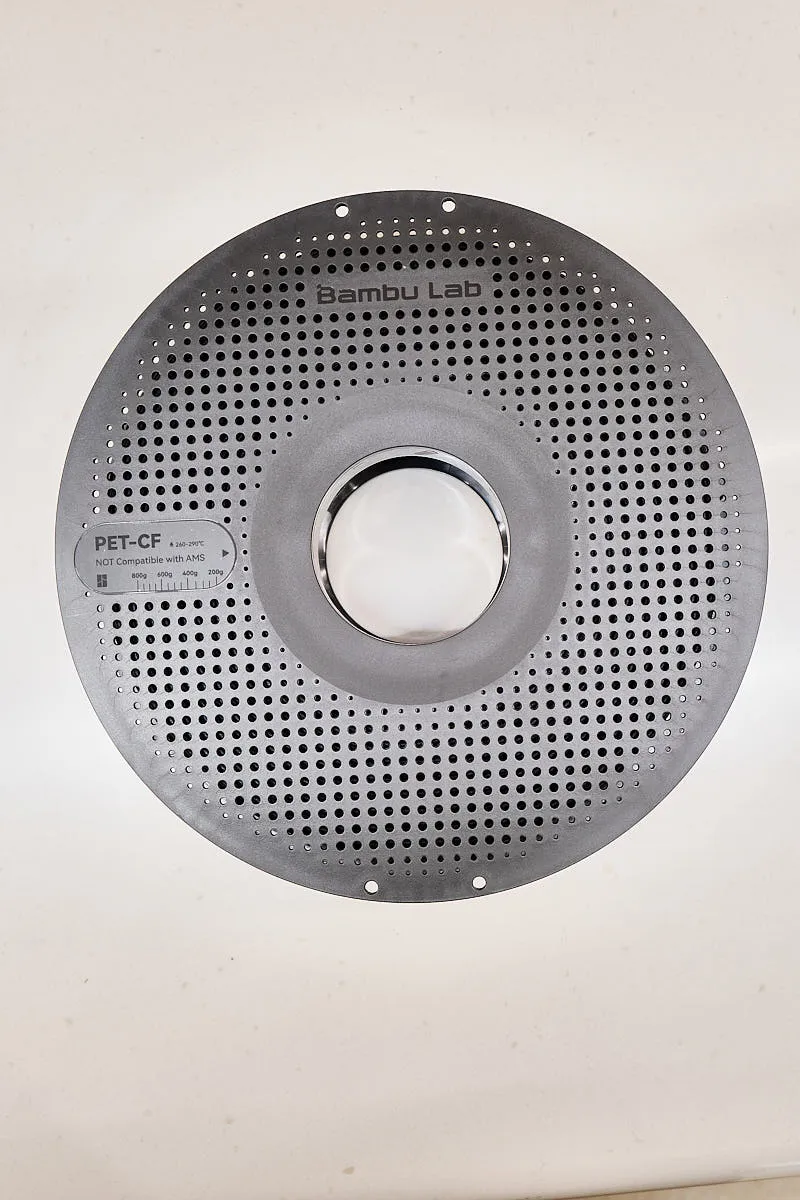

High-Temperature Reusable Spool

Bambu PET-CF comes mounted on a high-temperature resistant reusable spool designed to withstand filament drying and high-temperature printing conditions without deformation. Continuing Bambu Lab’s commitment to reducing plastic waste, the spool can be reused with compatible Bambu refill filaments, supporting both durability and sustainability.

Wholesale & Private Label Services

We offer wholesale and private label (OEM) services for a wide range of 3D printing accessories, including build plates, hotends, and related components.

More Options

Product videos

Printing Tips

• Drying conditions: 80℃ for 8 hrs. PET-CF is highly sensitive to humidity. To achieve optimal printing performance, it is recommended further drying before use and after storage. For more details, please refer to:Filament drying instructions on WIKI.

• To prevent the material from absorbing moisture, it is recommended to use an airtight storage container with desiccant during printing. For more details, please refer to:Printing tips for Engineering materials on WIKI.

FAQ

What is the difference between PET-CF and PETG-CF?

The primary difference between PET-CF and PETG-CF lies in their base material. PETG-CF is a reinforced material made by adding carbon fiber to glycol-modified polyethylene terephthalate (PETG), while PET-CF is to polyethylene terephthalate (PET). The key difference ‘G’ in PETG stands for glycol. PETG is a glycol-modified version of PET that contains small amounts of glycol as a co-monomer. The addition of glycol to PETG reduces its crystallinity and makes it more transparent. However, it also reduces its strength and stiffness.

The difference in application between PETG-CF and PET-CF?

PETG-CF is a versatile basic material that is suitable for printing everyday items, such as bent, folded, and movable parts, due to its excellent toughness and ease of printing. PET-CF, in contrast, contains a greater amount of carbon fiber and is significantly stronger and more temperature resistant compared to PETG-CF. PET-CF is a professional-grade engineering material that is suitable for use in more complex and demanding environments.

What is PET-CF used for?

Due to its dimensional stability and lower water absorption rate, PET-CF is a better choice than nylon for printing functional parts used in high humidity environments. Also, its high-temperature resistance and low warping make it suitable for printing mechanical assembly parts, such as automotive accessories and fixtures.

Specification

Accessory Compatibility

| Accessory Type | Recommended | Not Recommended |

|---|---|---|

| Build Plate | Cool Plate SuperTack, Smooth PEI Plate, Textured PEI Plate | / |

| Hotend | Hotend with Hardened Steel Nozzle 0.4 mm / 0.6 mm (Recommended) / 0.8 mm | Hotend with Stainless Steel Nozzle (All Sizes) |

| Glue | Glue Stick | Bambu Liquid Glue |

Parameters Comparison

| Parameter | PET-CF | PAHT-CF |

|---|---|---|

| Price / 1kg | £78.99 | £87.99 |

| Composition | PET, carbon fiber | PA 12 and other long-chain PA, carbon fiber |

| Hotend Compatibility | Hardened Steel 0.6 mm (Recommended), 0.4 mm, 0.8 mm | Hardened Steel 0.6 mm (Recommended), 0.4 mm, 0.8 mm |

| Build Plate Compatibility | Engineering Plate, High Temperature Plate, Textured PEI Plate | Engineering Plate, High Temperature Plate, Textured PEI Plate |

| Glue | Glue Stick / Liquid Glue | Glue Stick |

| AMS Compatibility | No | Yes |

| Print Speed | < 100 mm/s | < 100 mm/s |

| Toughness (Impact Strength – XY) | 36.0 kJ/m² | 57.5 kJ/m² |

| Strength (Bending Strength – XY) | 131 MPa | 125 MPa |

| Stiffness (Bending Modulus – XY) | 5320 MPa | 4230 MPa |

| Layer Adhesion (Impact Strength – Z) | 4.5 kJ/m² | 13.3 kJ/m² |

| Heat Resistance (HDT, 0.45 MPa) | 205 °C | 194 °C |

| Saturated Water Absorption Rate / % (25 °C, 55% RH) | 0.37% | 0.88% |

Recommended Printing Settings

| Recommended Printing Settings | Value |

|---|---|

| Drying Settings (Blast Drying Oven) | 80 °C, 8 – 12 h |

| Printing and Keeping Container’s Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 260 – 290 °C |

| Bed Temperature (with Glue) | 80 – 100 °C |

| Printing Speed | < 100 mm/s |

Physical & Mechanical Properties

|

|

Bambu Lab PET-CF Black Filament with Spool

Bambu Lab PET-CF Black Filament with Spool

Reviews

There are no reviews yet