- Low Moisture Absorption

- Exceptional Mechanical Properties & Layer Adhesion

- High Tensile Strength

- Comes with High Temperature Reusable Spool

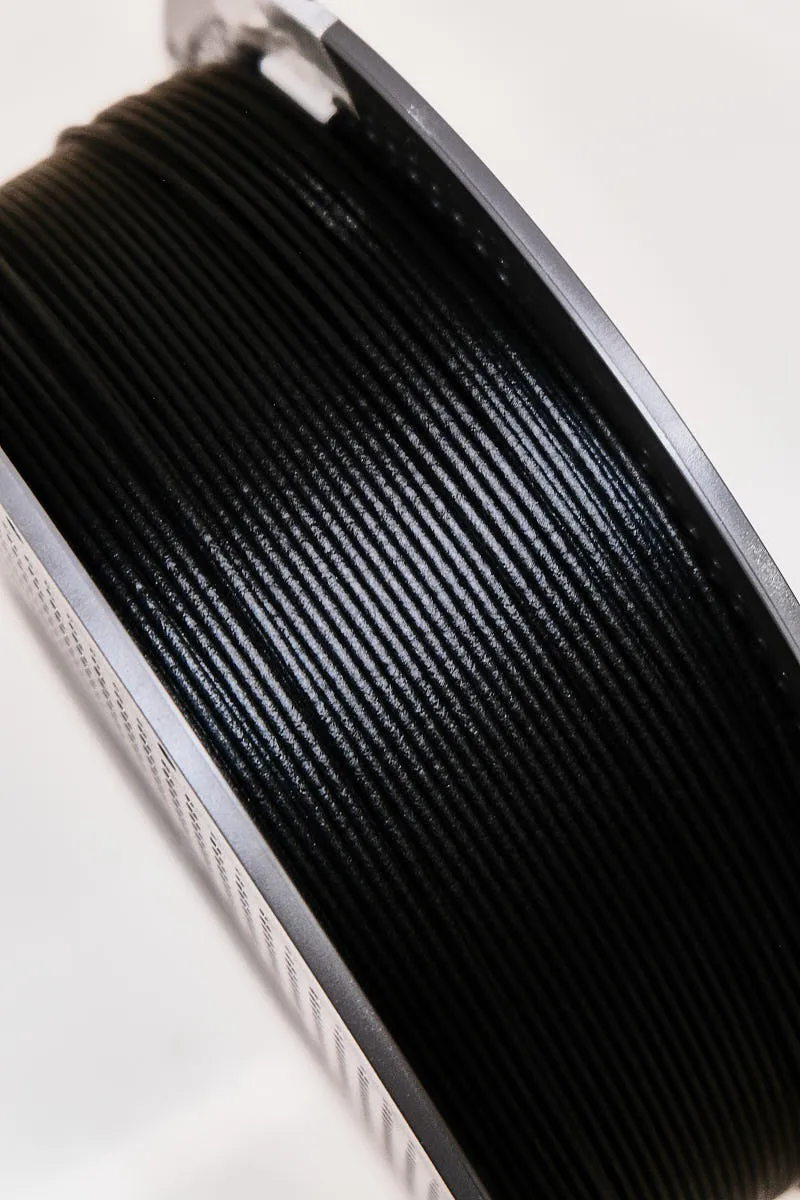

- Diameter: 1.75mm +/- 0.03mm

- 0.6 mm Nozzle Recommended

- 0.2 mm Nozzle NOT Compatible

- Stainless Steel Nozzle NOT Recommended

- AMS 2 Pro, AMS HT & AMS Compatible

- AMS lite NOT Compatible

- Dry before Use for the Highest Print Quality

- Enclosure Printer Required

- Color Code: 70100

Looking for other products of Bambu Lab?

Description

Bambu PAHT-CF Overview

Bambu PAHT-CF is a composite material made from PA12 and carbon fiber. By combining the low water absorption of PA12 with the high strength of carbon fiber, it delivers excellent mechanical and thermal performance that remains stable even in wet or high-humidity environments. With enhanced Z-layer adhesion and balanced flexibility, it is ideal for engineering parts such as functional prototypes, machining fixtures, injection molds, jigs, and low-volume production components.

Low Water Absorption

With a water absorption rate approximately 50% lower than that of normal PA-CF, Bambu PAHT-CF maintains excellent mechanical properties and dimensional stability even when exposed to high humidity. This makes it highly reliable for applications where environmental moisture is a concern.

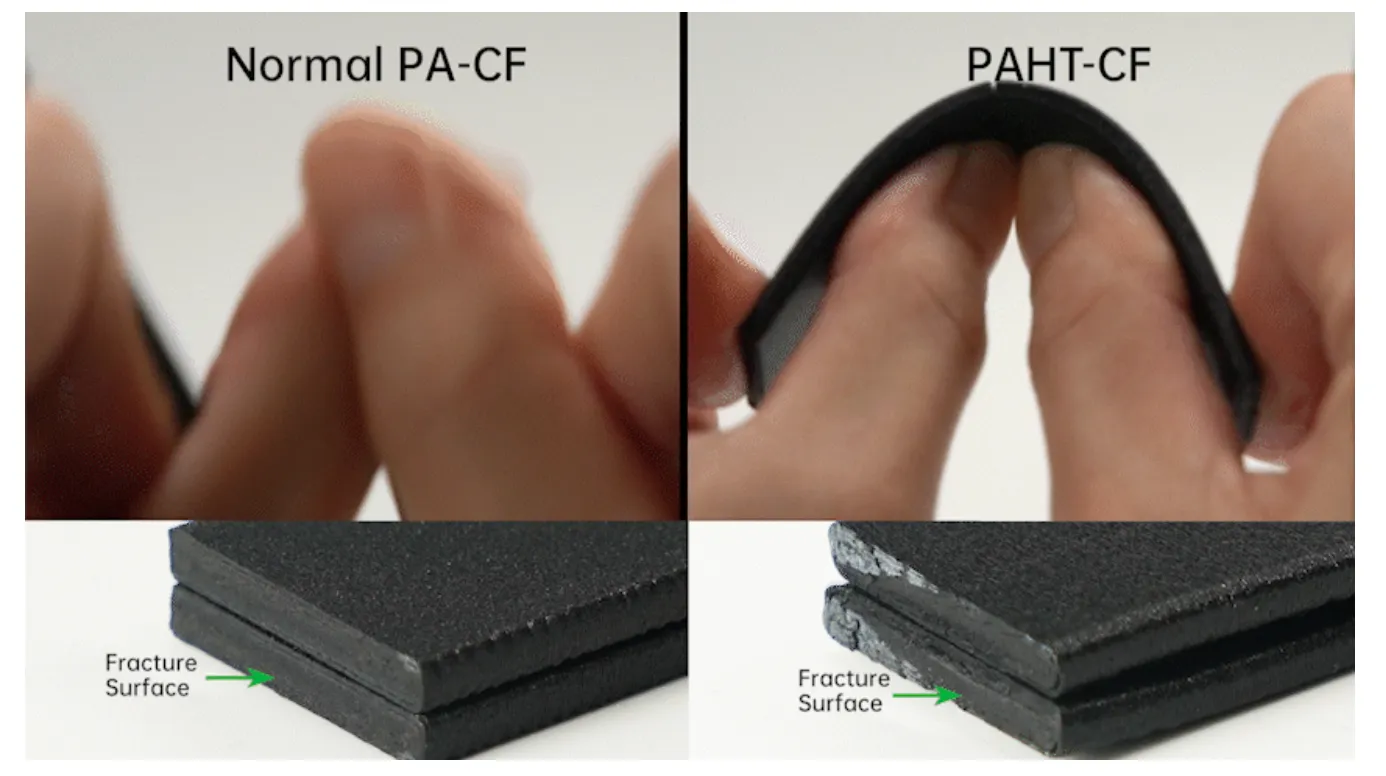

Exceptional Z-Bonding Performance

Bambu PAHT-CF exhibits significantly higher Z-layer adhesion compared to normal PA-CF. This enhanced interlayer bonding allows printed parts to withstand high levels of impact and mechanical stress without cracking, delaminating, or deforming.

High Tensile Strength

Engineered for demanding industrial and engineering applications, Bambu PAHT-CF delivers high tensile strength and durability. It is well suited for functional components that require reliable load-bearing performance and long-term structural stability.

Designed for High-Temperature Resistance

Bambu PAHT-CF offers a heat deflection temperature of up to 194 °C at 0.45 MPa, enabling printed parts to perform reliably in high-temperature environments. This makes it suitable for applications where heat resistance is critical without compromising strength or dimensional accuracy.

RFID-Enabled Intelligent Printing

All print parameters are embedded in RFID and automatically recognized by the Bambu Lab AMS system, enabling seamless material identification and eliminating manual setup steps.

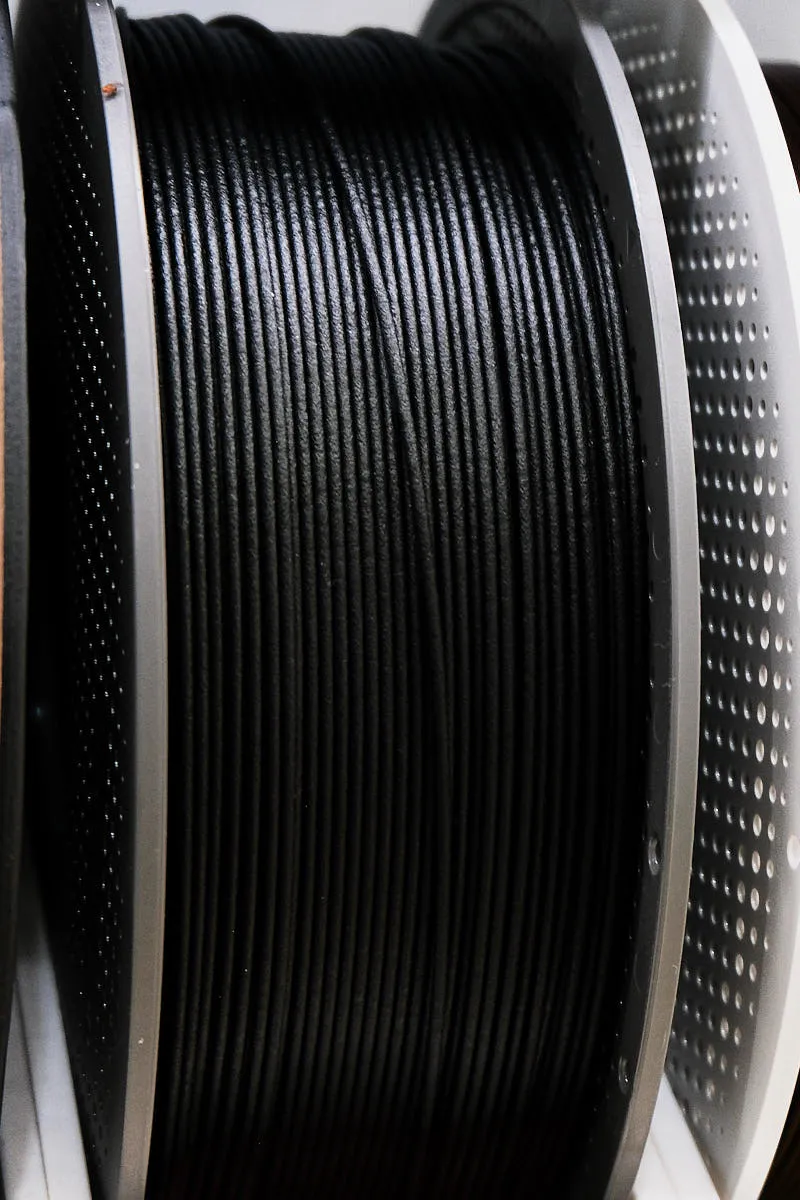

High-Temperature Reusable Spool

Bambu PAHT-CF is supplied on a high-temperature-resistant spool that is not prone to deformation during the drying process. In line with Bambu’s commitment to reducing plastic waste, the spool is reusable and compatible with other Bambu refill filaments.

Wholesale & Private Label Services

We offer wholesale and private label (OEM) services for a wide range of 3D printing accessories, including build plates, hotends, and related components.

More Options

Product videos

Printing Tips

•Drying conditions: 80℃ for 8 hrs. PAHT-CF is highly sensitive to humidity. To achieve optimal printing performance, it is recommended further drying before use and after storage. For more details please refer to: Filament drying instructionson WIKI.

• Bambu PAHT-CF has high thermal insulation requirements during the printing process, making it unsuitable for use with open-frame printers.

• When printing a model with support, we recommend removing the support structures within 2 hours after printing to prevent them from sticking after absorbing moisture. If sticking occurs, dry the model to ease the removal.

• For better print results, please refer to: Printing tips for Engineering materials on WIKI.

Specification

Mechanical Properties Comparison

| Mechanical Properties Comparison | Normal PA-CF | PAHT-CF |

|---|---|---|

| Saturated Water Absorption Rate / % (25 °C, 55% RH) | 1.70 | 0.88 |

| Bending Strength – XY / MPa (Dry) | 128 | 125 |

| Bending Strength – XY / MPa (Wet) | 76 | 115 |

| Bending Strength – Z / MPa (Dry) | 48 | 61 |

| Bending Strength – Z / MPa (Wet) | 34 | 49 |

| Bending Modulus – XY / MPa (Dry) | 4420 | 4230 |

| Bending Modulus – XY / MPa (Wet) | 2210 | 3640 |

| Bending Modulus – Z / MPa (Dry) | 1470 | 1820 |

| Bending Modulus – Z / MPa (Wet) | 770 | 1480 |

| Decline Rate of Mechanical Properties After Water Absorption / % | 40% – 45% | 12% – 18% |

Z-layer Performance

| Property | Normal PA-CF | PAHT-CF | Improved % |

|---|---|---|---|

| Bending Strength – Z / MPa | 48 | 61 | 27% |

| Bending Modulus – Z / MPa | 1470 | 1820 | 24% |

| Impact Strength – Z / (kJ/m²) | 5.7 | 13.3 | 133% |

* Both PA-CF and PAHT-CF need to be dried at 80 °C for 12 hours before printing.

Accessory Compatibility

|

ACCESSORY TYPE Build Plate |

RECOMMENDED Smooth PEI Plate, Textured PEI Plate |

NOT RECOMMENDED Cool Plate SuperTack |

|

ACCESSORY TYPE Hotend |

RECOMMENDED Hotend with Hardened Steel Nozzle 0.4 mm / 0.6 mm (Recommended) / 0.8 mm |

NOT RECOMMENDED Hotend with Stainless Steel Nozzle (All Sizes) |

|

ACCESSORY TYPE Glue |

RECOMMENDED Glue Stick |

NOT RECOMMENDED Liquid Glue |

* As the nozzle size increases, the probability of clogging decreases, but print quality may be reduced.

For an optimal balance between clog resistance and print quality, a

0.6 mm Hardened Steel nozzle is recommended.

Recommended Printing Settings

| Recommended Printing Settings | Value |

|---|---|

| Drying Settings (Blast Drying Oven) | 80 °C, 8 – 12 h |

| Printing and Keeping Container’s Humidity | < 20% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 260 – 290 °C |

| Bed Temperature (with Glue) | 80 – 100 °C |

| Printing Speed | < 100 mm/s |

Physical & Mechanical Properties

|

|

Parameters Comparison

| Property | PET-CF | PAHT-CF |

|---|---|---|

| Composition | PET, carbon fiber | PA 12 and other long-chain PA, carbon fiber |

| Hotend Compatibility | Hardened Steel 0.6 mm (Recommended), 0.4 mm, 0.8 mm | Hardened Steel 0.6 mm (Recommended), 0.4 mm, 0.8 mm |

| Build Plate Compatibility | Engineering Plate, High Temperature Plate, Textured PEI Plate | Engineering Plate, High Temperature Plate, Textured PEI Plate |

| Glue | Glue Stick / Liquid Glue | Glue Stick |

| AMS Compatibility | NO | YES |

| Print Speed | < 100 mm/s | < 100 mm/s |

| Toughness (Impact Strength – XY) | 36.0 kJ/m² | 57.5 kJ/m² |

| Strength (Bending Strength – XY) | 131 MPa | 125 MPa |

| Stiffness (Bending Modulus – XY) | 5320 MPa | 4230 MPa |

| Layer Adhesion (Impact Strength – Z) | 4.5 kJ/m² | 13.3 kJ/m² |

| Heat Resistance (HDT, 0.45 MPa) | 205 °C | 194 °C |

| Saturated Water Absorption Rate / % (25 °C, 55% RH) | 0.37 | 0.88 |

Bambu Lab PAHT-CF Black Filament with Spool

Bambu Lab PAHT-CF Black Filament with Spool

Reviews

There are no reviews yet