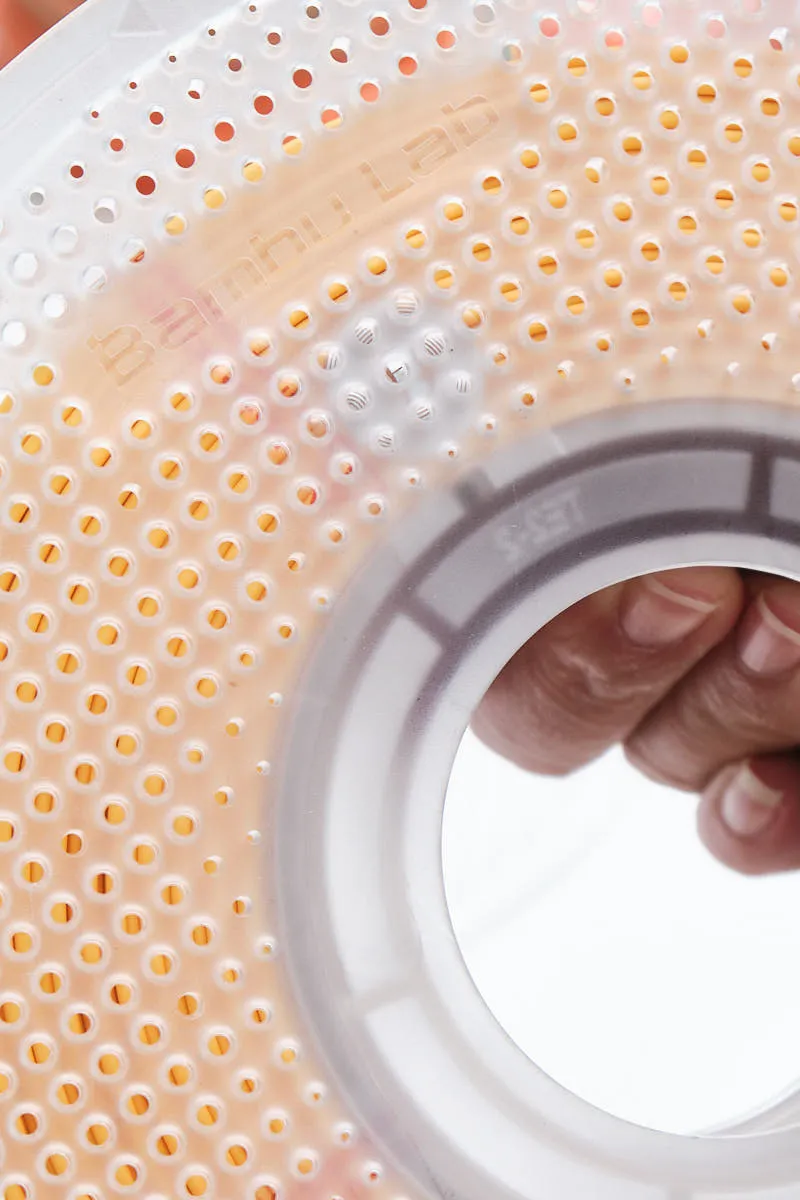

- Seamless AMS & AMS lite Integration

- Tough Yet Flexible

- Less TPU Stringing

- Blazing Fast TPU Printing

- Comes with High Temperature Reusable Spool

- Diameter: 1.75 mm +/- 0.05 mm

- AMS & AMS lite Compatible

Looking for other products of Creality?

Specification

Blazing Fast TPU Printing

| Specification | Bambu TPU for AMS | Bambu TPU 95A HF |

| Nozzle Temperature [°C] | 230 | 230 |

| Max Volumetric Speed [mm³/s] | 18 | 12 |

| Printing Speed [mm/s] | Up to 238 | Up to 147 |

| Model Specimens | Diameter: 50mm Height: 100mm Infill: 40% | |

Recommended Printing Settings

| Recommended Nozzle Temp. [°C] | Recommended Bed Temp. [°C] | Drying Temp. [°C] | Printing Speed [mm/s] | Humidity [RH] | Drying Time [h] |

| 220 – 240 | 30 – 35 | 70 | < 250 | < 20% | 8 |

Accessory Compatibility

| Component | Recommended | Not Recommended |

| Build Plate |

Smooth PEI Plate Textured PEI Plate |

/ |

| Hotend |

Hardened Steel Nozzle 0.4 mm Hardened Steel Nozzle 0.6 mm Hardened Steel Nozzle 0.8 mm |

Stainless Steel Nozzle 0.4 mm Hardened Steel Nozzle 0.2 mm Stainless Steel Nozzle 0.2 mm |

| Glue | Bambu Liquid Glue | / |

| Glue Stick | / | / |

| AMS & AMS lite | AMS & AMS lite | / |

Physical & Mechanical

| Density [g/cm³] | Vicat Softening Temp. [°C] | Heat Deflection Temp. [°C] | Melting Temp. [°C] | Melt Index [g/10 min] | Tensile Strength [MPa] |

| 1.26 | N / A | N / A | 183 | 21.8 ± 0.3 | 22.4 ± 0.6 |

| Breaking Elongation [%] | Bending Modulus [MPa] | Bending Strength [MPa] | Impact Strength | ||

| > 650 | N / A | N / A | N / A | ||

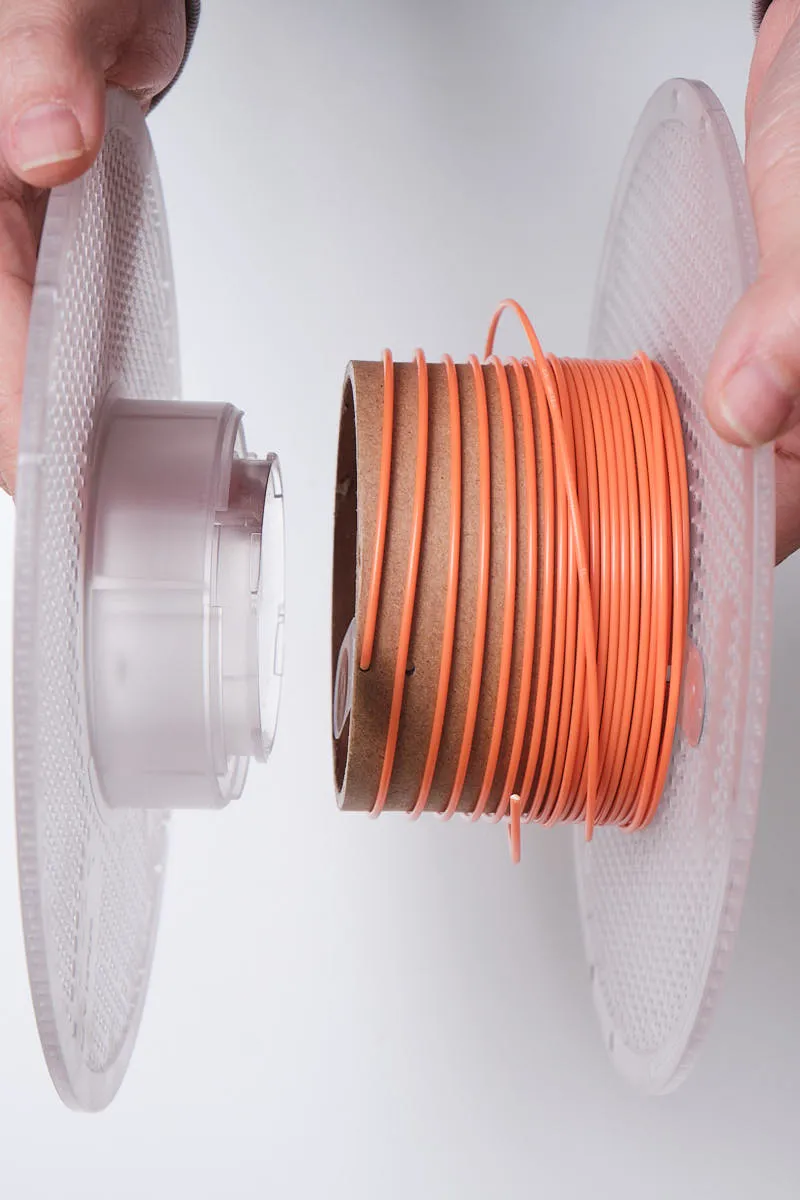

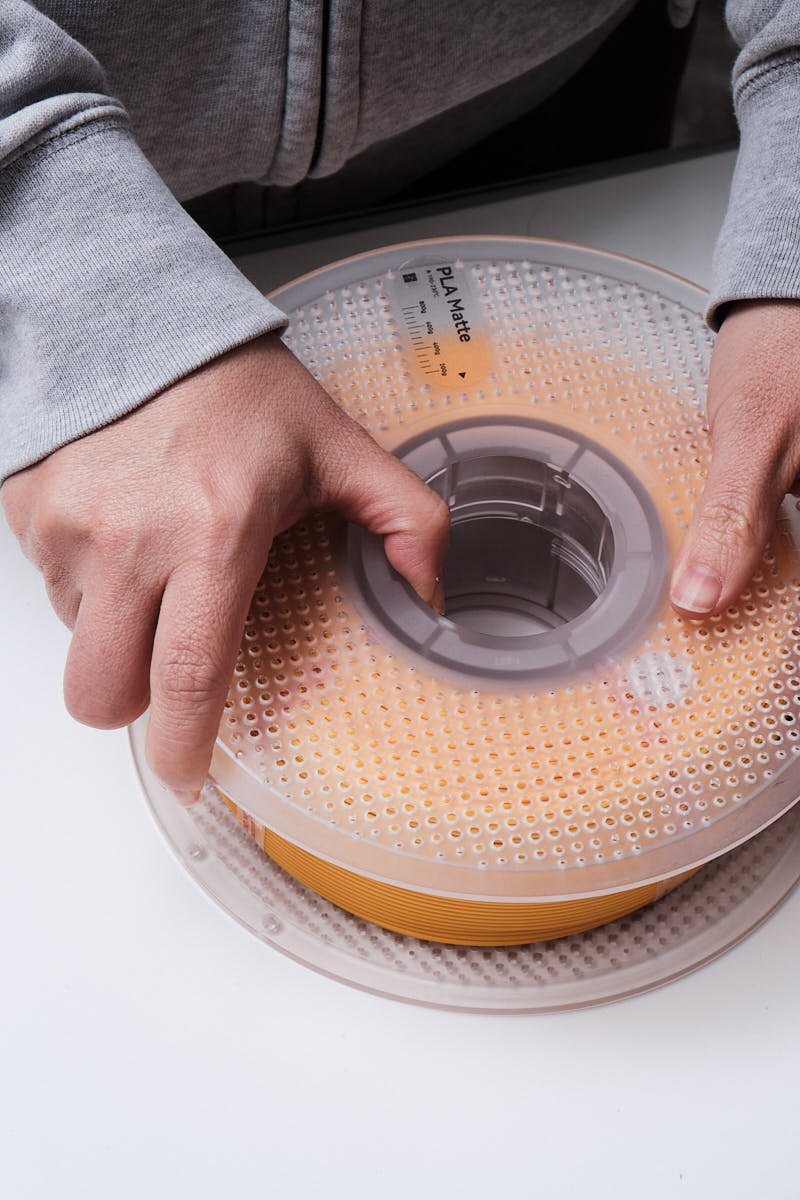

Dimensions Filament Spool

| Spool Type | Content [g] | Width [mm] | Outer Diameter [mm] | Inner Diameter [mm] | Material |

| Standard / Reusable Spool | 500 / 1000 | 67 | 200 | 55 | Plastic |

| Cardboard Spool | 750 | 67 | 200 | 55 | Cardboard |

| Refill | — | ≈ 60 | ≈ 170 | ≈ 80 | — |

Description

TPU Optimized for AMS Printing

Bambu TPU for AMS is specially developed to deliver a smoother and more reliable TPU printing experience with full AMS compatibility. It enables flexible materials to be used confidently in multicolor printing, expanding creative possibilities while maintaining consistent print quality and stability.

Seamless AMS & AMS Lite Integration

Precisely tuned for the AMS and AMS Lite systems, Bambu TPU for AMS ensures smooth filament feeding and dependable multicolor printing. Its optimized formulation allows flexible materials to perform reliably within automated material systems without common TPU handling issues.

Tough Yet Flexible Performance

With a Shore hardness of 68D, Bambu TPU for AMS strikes a balanced combination of strength and flexibility. It produces durable, impact-resistant parts while retaining TPU’s signature elasticity, making it suitable for protective cases, phone covers, sports gear, automotive components, and other functional applications.

Reduced Stringing for Cleaner Prints

Thanks to its advanced material formulation, Bambu TPU for AMS significantly reduces stringing commonly seen in traditional TPU filaments. This results in cleaner surfaces, sharper details, and more reliable prints with minimal post-processing required.

High-Speed TPU Printing

Designed for efficiency, Bambu TPU for AMS supports printing speeds up to 60% faster than conventional TPU materials such as TPU 95A HF. This allows you to complete flexible material projects more quickly without sacrificing print quality or consistency.

RFID-Enabled Smart Printing

All essential printing parameters are embedded directly into the filament’s RFID chip, allowing the AMS to automatically recognize and apply optimal settings. Simply load the filament and start printing—no manual configuration required.

Consistent Results with Flexible Print Settings

Please note that the final transparency of printed parts may vary depending on model size, geometry, and printing parameters such as speed, nozzle temperature, layer height, and infill density. Fine-tuning these settings allows you to control the balance between strength and translucency.

Eco-Friendly Refill Option

Bambu Lab Refills are part of an innovative filament system designed to optimize filament handling while reducing environmental impact.

By combining reusable spools, refill filaments, and intelligent material management, this system delivers a more sustainable and efficient 3D printing experience.

Flexible Control of Elasticity

The elasticity of TPU prints can be fine-tuned through wall loops and sparse infill density settings. Increasing wall loops or infill density enhances rigidity, while lower values improve flexibility, giving you precise control over the final mechanical behavior of your printed parts.

Wholesale & Private Label Services

We offer wholesale and private label (OEM) services for a wide range of 3D printing accessories, including build plates, hotends, and related components.

More Options

Product videos

Printing Tips

- 0.2 mm Nozzle Not Compatible

- Dry Before Use

- Dry before use for higher printing quality. TPU for AMS must be dried before use and kept moisture-free during the printing process to prevent stringing.

- Drying conditions: 70℃ for 8 hrs in a blast drying oven, or 80°C to 90°C for 12 hours on an X1 printer’s heatbed. For more details please refer to: Filament drying instructions on WIKI.

- Storage tips: To prevent the filament from absorbing moisture, use an airtight storage container with desiccant during printing.

Bambu Lab Black TPU for AMS Filament 1.75mm 1kg

Bambu Lab Black TPU for AMS Filament 1.75mm 1kg

Reviews

There are no reviews yet