How 3D Printer Filament Is Made – From Pellets to Precision Printing

If you’ve ever stocked up on 3D printer filament only to find it sitting unused in a drawer months later, you’ve probably wondered: how long does 3D printer filament actually last?

Unlike many craft or hobby materials, filament doesn’t have a strict “expiration date,” but its ability to produce reliable prints can diminish over time depending on how it’s stored and what type of material it is.

Whether you’re a beginner trying to understand how long your PLA, ABS, or PETG can stay usable, or an experienced maker looking to optimize filament storage and inventory, this guide breaks down everything you need to know.

We’ll explore how different filament materials age, what environmental factors affect their lifespan, how to tell if a spool has degraded, and practical tips to keep your filament in peak condition. By the end of this guide, you’ll have a clear understanding of how long your 3D printer filament can realistically last—and how to make it last even longer.

1.Understanding Filament Lifespan

Filament lifespan is the period during which the material maintains its physical and printing properties well enough to give consistent results. It depends on material properties and how the filament is stored, not on a printed expiration date.

2. Average Shelf Life of Common Filament Types

| Filament Type | Unopened, Sealed | Opened & Dry | Opened & Air Exposed |

|---|---|---|---|

| PLA | ~2–3+ years | ~1–2 years | ~3–6 months |

| ABS | ~3–5+ years | ~2–4 years | ~6–12 months |

| PETG | ~3–5+ years | ~2–4 years | ~6–12 months |

| Nylon / PA | ~1–2 years | ~1–2 years | ~3–6 months |

| Exotic Blends | ~1–2 years | ~1–2 years | ~3–6 months |

2.1 PLA Filament Lifespan

Typical lifespan ranges (1–2 years unopened / 3–6 months opened)

PLA filament stored unopened in proper conditions (cool, dry, away from sunlight) will generally remain usable for about 1–2 years or more before noticeable degradation occurs, and opened spools tend to stay in good printing condition for around 3–6 months on average.

Why does PLA age faster (moisture absorption)

PLA tends to absorb moisture from the air over time, which can cause issues like bubbling, reduced layer adhesion, and brittle filament during printing. Even small amounts of water absorbed into the filament impact its consistency and print quality.

2.2 ABS Filament Lifespan

Typical shelf life and characteristics

ABS filament generally lasts around 2–3 years if stored properly sealed and dry. When exposed to air and humidity, its usable life may be shorter.

How ABS compares to PLA

ABS is more resistant to moisture and heat than PLA, so it tends to maintain its properties longer, especially in stable storage

2.3 PETG Filament Longevity

PETG typically stays usable for about 2–3 years when unopened and stored in dry conditions, and 4–5 years or more is possible with excellent storage.

Moisture and heat resistance

PETG has better moisture and chemical resistance than PLA, which helps it resist degradation longer.

2.4 Nylon and Other Hygroscopic Filaments

Why nylon degrades quicker

Nylon and other hygroscopic materials tend to have shorter usable lifespans, around 6–12 months when exposed to air and about 1–2 years if kept dry and sealed.

Factors that shorten lifespan significantly

Nylon absorbs moisture very quickly, which leads to bubbling, inconsistent extrusion, and weakened prints if not dried and stored in a low-humidity environment.

3. Top Factors That Affect Filament Lifespan

3.1 Moisture absorption causes brittleness & poor prints

Most 3D printing filaments are hygroscopic, meaning they absorb water from the air over time.

When filament absorbs moisture, it can become brittle, swell, and lead to printing issues such as bubbling, inconsistent extrusion, rough surfaces, and weak layer adhesion.

Keeping filament dry is essential for maintaining print quality.

3.2 Temperature and Heat Exposure

Heat speeds up aging

High temperatures accelerate the breakdown of the polymer chains in filament. Long-term exposure to heat — even below melting point — can cause changes in material properties, such as softening, warping, or permanent deformation, which negatively impacts printing performance.

3.3 UV Light and Sunlight Exposure

Ultraviolet (UV) light from the sun or strong artificial sources breaks down filament at the molecular level. UV exposure can cause discolouration, loss of strength, and increased brittleness, shortening the usable life of the filament.

3.4 Packaging and Handling

Filament spools are typically shipped with airtight bags and desiccant packs to minimize moisture exposure. Keeping filament in its original sealed packaging or in a dry box helps prevent premature aging. Improper handling — leaving spools open or exposed — allows moisture and contaminants in, which speeds up degradation.

4. How to Store Filament to Extend Its Life

4.1 Airtight containers, desiccants, humidity control

The most effective way to preserve filament is to store it in airtight containers or sealed bags with desiccant packs to absorb moisture.

Keeping filament in a cool, dry place with consistent humidity (ideally below ~20–30% RH) prevents absorption and extends usable life.

4. 2 Dry boxes, silica gel, regular monitoring

Insufficient pre-mixing can result in localized pigment concentration during extrusion.

This leads to visible color streaks, inconsistent filament appearance, and unstable extrusion behavior.

Proper pre-mixing ensures consistent color along the entire length of the filament.

4. 3 Climate-Specific Storage Advice

In high-humidity regions, using dehumidifiers or actively controlled dry cabinets can make a significant difference.

In dry climates, sealed containers with basic desiccants may suffice.

Adjust your storage method based on local climate conditions to keep filament dry and stable.

5. How to Tell If Your Filament Has Gone Bad

5.1 Visual & Physical Inspection

Brittle, snapping filament

If the filament breaks easily when bent or feels dry and crumbly, it has likely absorbed moisture or aged beyond its useful condition.

Colour/texture changes

Discoloration, dullness, or uneven texture can be a sign of degradation or UV exposure.

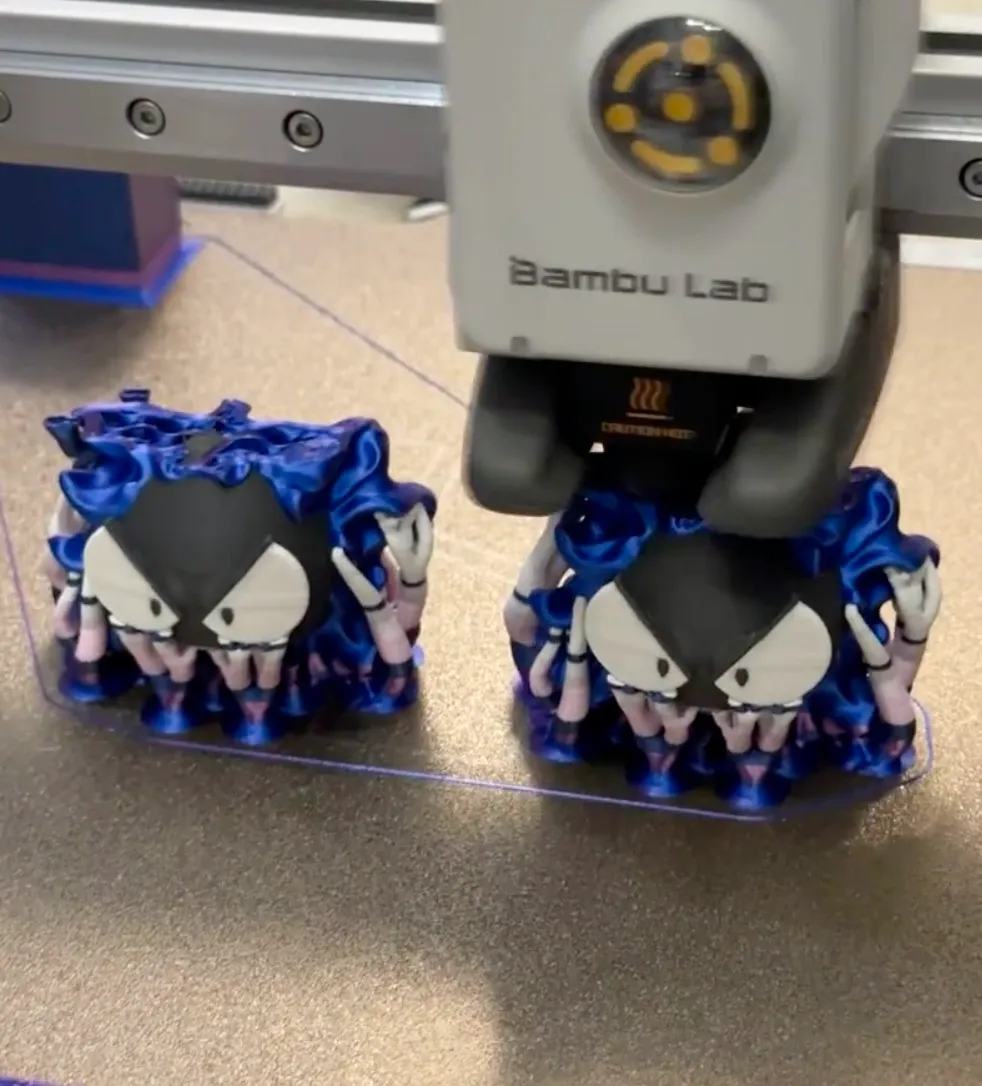

5.2 Print Test Signs

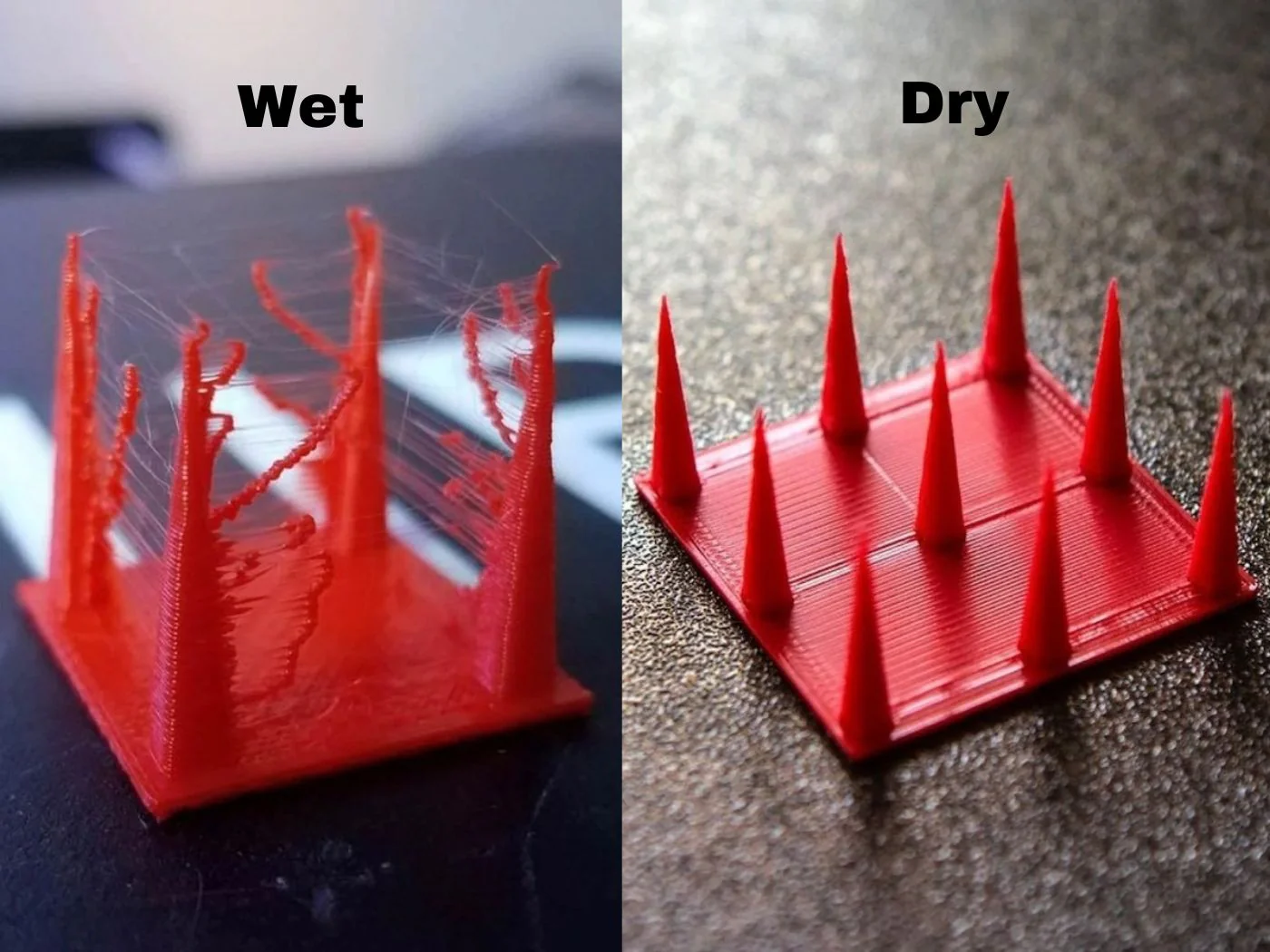

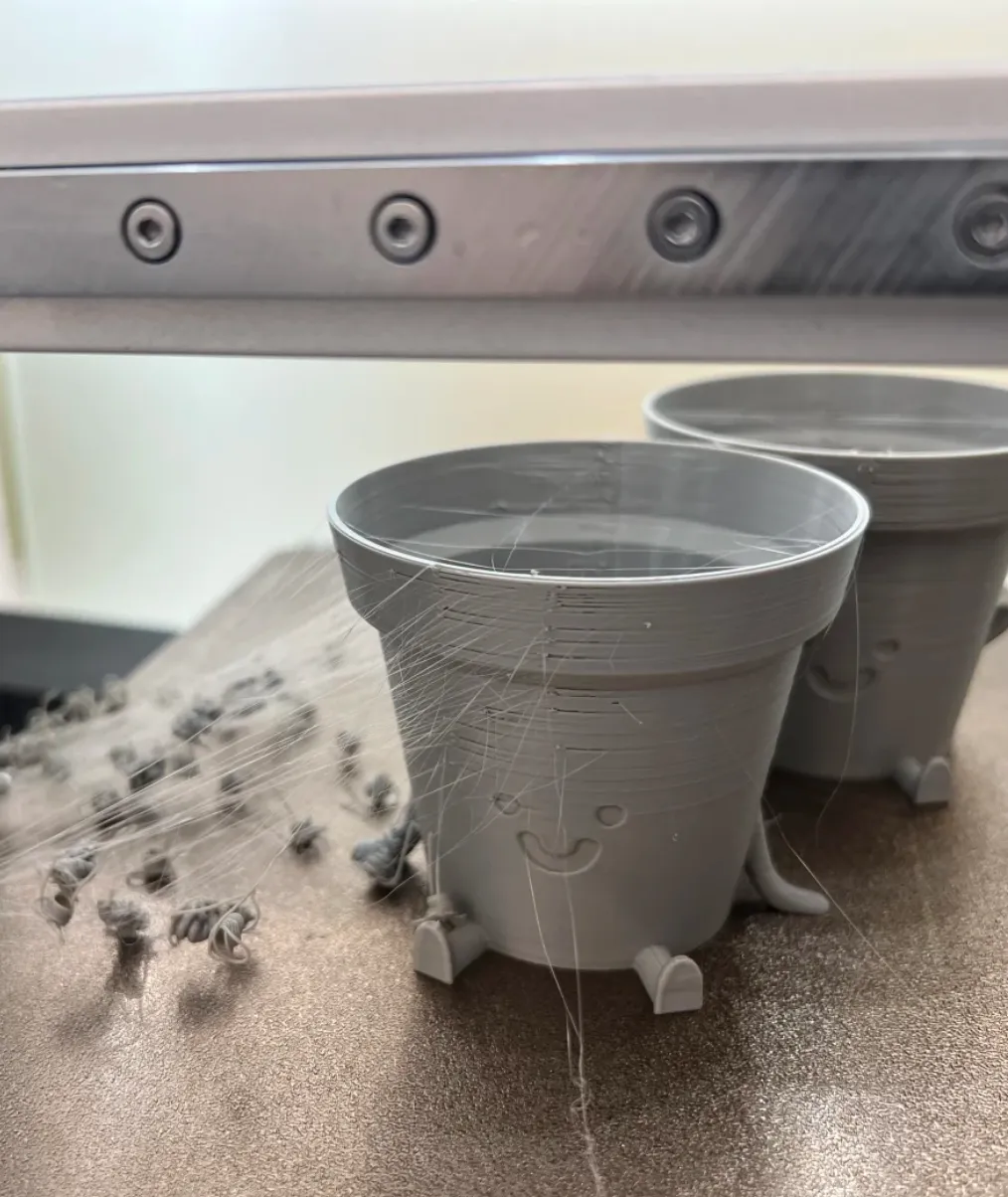

When filament has degraded or absorbed moisture, printed parts may show excessive stringing, bubbles, inconsistent extrusion, or rough surfaces. These are common visual clues during a test print.

5.4 Moisture Damage Symptoms

Rough finish, layer adhesion issues

Filament that has taken on moisture often produces prints with rough surfaces, poor layer bonding, or weak spots. These moisture-related print defects are reliable indicators that the filament is no longer in optimal condition.

6. Additional Questions You Might Have (FAQ)

6.1 Does Extra Material Like Wood / Metal Blends Change Lifespan?

Additives may accelerate aging

Filament blends that include additives (like wood, metal, carbon fiber) often have higher susceptibility to moisture and wear

.These materials can degrade faster than pure PLA or PETG, so they may have a shorter effective lifespan if not stored carefully.

6.2 If Filament Has Absorbed Moisture, Can It Be Dried and Printed Again?

Yes — in most cases moisture-affected filament can be dried and then used for printing again.

When filament absorbs humidity, it often causes problems like stringing, bubbles, and poor surface finish because the water vaporizes in the hotend during printing.

Drying the filament at an appropriate low temperature (often in a filament dryer or controlled oven) helps remove the absorbed moisture and can restore good print performance.

7. Filament Usage vs Lifespan — How Much Can You Print?

7.1 How long does a 1kg filament spool last

Printing time estimates and examples

The amount of printing you can do with a 1 kg spool depends on your model size, infill density, and print settings.

A standard 1 kg PLA spool contains roughly 300–330 meters of filament, which can produce dozens to hundreds of parts depending on complexity.

A small toy might use only a few meters, while a large functional part could use tens of meters.

7.2 Factors That Affect Consumption

- Model size: larger parts use more material

- Infill percentage: higher infill = more filament

- Print speed and layer height: finer resolution requires more passes and increases filament use

Conclusion

3D printer filament doesn’t expire like food, but its performance declines with age and poor storage. Most filaments last 1–2 years or more when sealed, with opened spools remaining usable for several months under good conditions.

• Actionable storage & handling tips

• Store filament in airtight containers with desiccants

• Keep it in a cool, dry, dark place

• Use dry boxes or sealed tubs for open spools

• Monitor for brittleness, moisture signs, or print defects as indicators of degradation

Found this useful? Share or subscribe for more 3D printing tips!

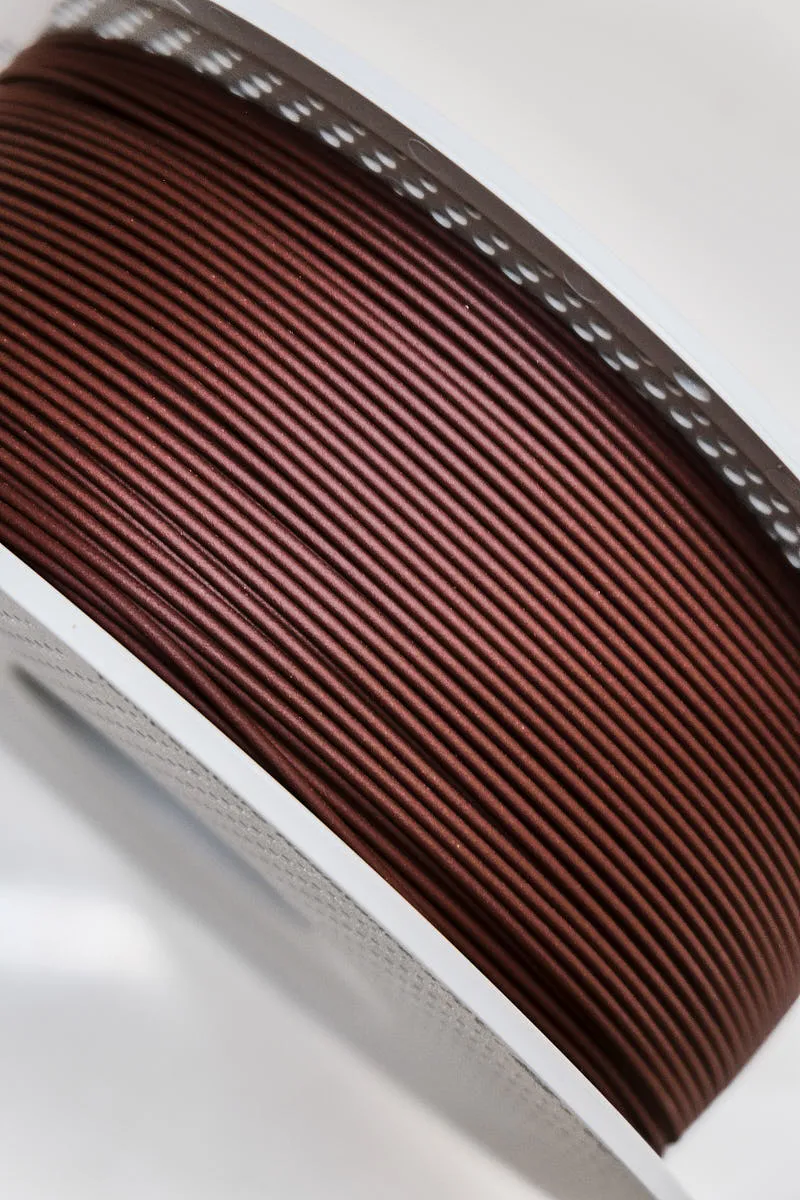

OEM & Wholesale Filament Services by VoxelFuse3D

Private label and OEM filament manufacturing

VoxelFuse3D provides OEM and private label filament manufacturing for brands and distributors.

Services include material selection, color formulation, diameter specification, packaging, and branding, with production managed under controlled manufacturing standards.

Wholesale supply of established filament brands

VoxelFuse3D provides OEM and private label filament manufacturing for brands and distributors.

Services include material selection, color formulation, diameter specification, packaging, and branding, with production managed under controlled manufacturing standards.

Professional sourcing with stable pricing and quality assurance

VoxelFuse3D provides OEM and private label filament manufacturing for brands and distributors.

Services include material selection, color formulation, diameter specification, packaging, and branding, with production managed under controlled manufacturing standards.