How 3D Printer Filament Is Made – From Pellets to Precision Printing

1. Everything Starts as Plastic Pellets

1.1 What are raw filament pellets

3D printer filament is manufactured from industrial plastic pellets, not from recycled filament or pre-formed strands.

These pellets are virgin or controlled-grade polymers such as PLA, PETG, or ABS, produced in standardized shapes and sizes.

Their geometry and composition are designed to ensure predictable melting behavior during extrusion.

1.2 Why material consistency matters

Consistent pellet size and composition are critical for stable material flow and uniform melting.

Variations in pellet quality can lead to uneven extrusion, diameter fluctuation, and mechanical instability in the final filament.

High-quality filament production begins with tightly controlled raw materials.

2. Color Isn’t Paint – It’s a Formula

2.1 What is color masterbatch?

Color in 3D printer filament is achieved through color masterbatch, not surface coating or post-processing.

A color masterbatch is a highly concentrated mixture of pigments and carrier resin, designed to blend uniformly with base polymer pellets.

It ensures stable color performance during melting and extrusion.

2.2 Why precise ratios are critical

Color masterbatch is added by weight using fixed formulations.

Incorrect ratios can cause color inconsistency, material property changes, and extrusion instability.

Accurate dosing is required to maintain both visual consistency and mechanical performance of the filament.

3. Pre-mixing – Making Color Uniform

3.1 Physical blending before melting

Before extrusion, base polymer pellets and color masterbatch are mechanically mixed inblending equipment.

This step distributes the color masterbatch evenly throughout the raw material without applying heat.

The goal is to achieve uniform material composition prior to melting.

3.2 Why this step prevents streaking

Insufficient pre-mixing can result in localized pigment concentration during extrusion.

This leads to visible color streaks, inconsistent filament appearance, and unstable extrusion behavior.

Proper pre-mixing ensures consistent color along the entire length of the filament.

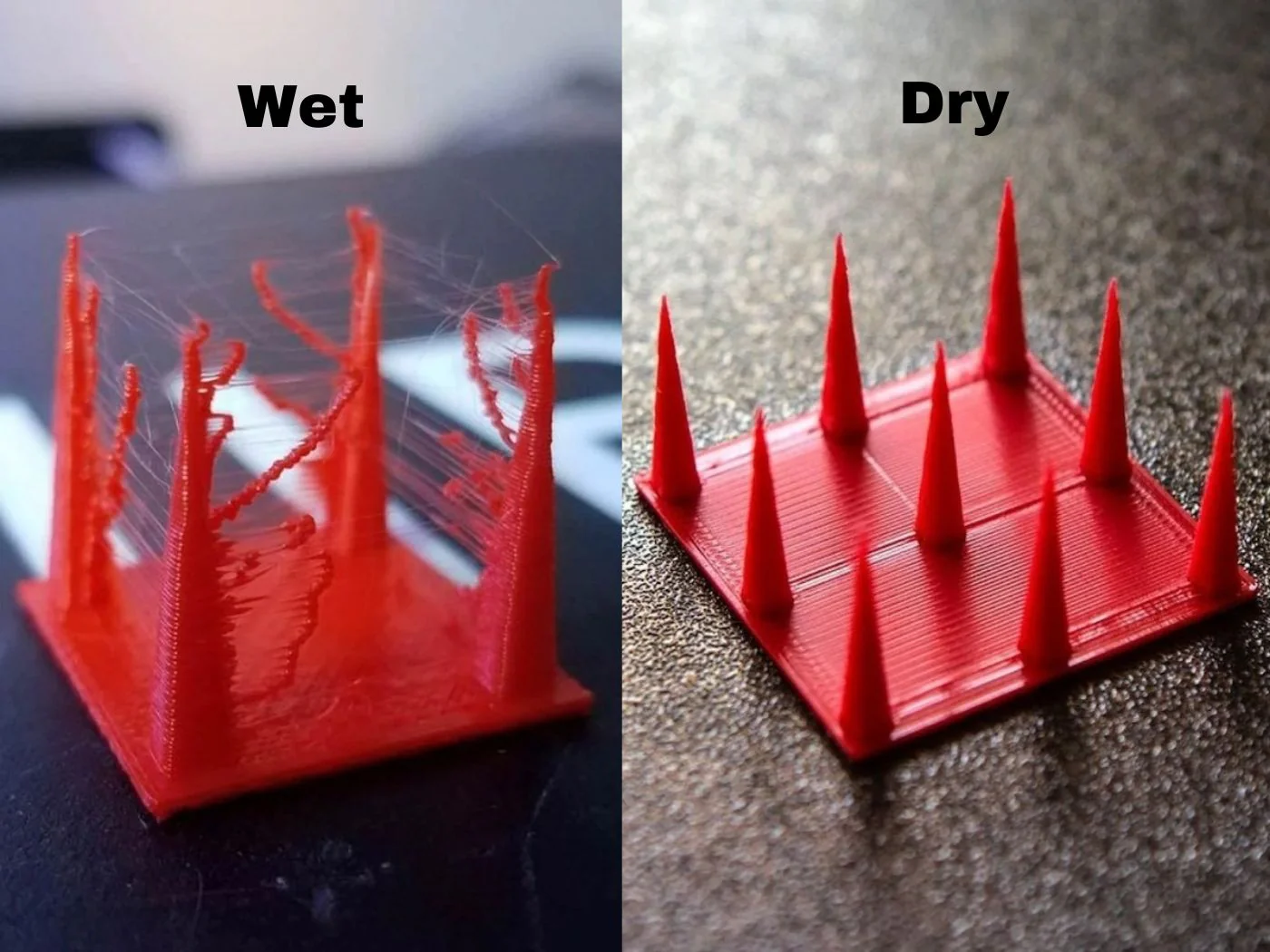

4. Drying – The Step Most People Ignore

4.1 Moisture-related issues in filament

Before extrusion, base polymer pellets and color masterbatch are mechanically mixed inblending equipment.

This step distributes the color masterbatch evenly throughout the raw material without applying heat.

The goal is to achieve uniform material composition prior to melting.

4.2 Industrial drying vs home drying

Industrial filament production uses controlled drying systems with stable temperature and airflow.

These systems remove moisture from raw pellets before extrusion, not from finished filament.

Home filament dryers can reduce moisture after packaging, but they cannot replace proper pre-extrusion drying during manufacturing.

5. From Pellets to Melt – Feeding the Extruder

5.1 Transition from solid pellets to molten material

Dried pellets are fed into the extruder, where they move through a heated barrel by a rotating screw.

As the pellets advance, they are gradually heated and compressed until fully molten.

This controlled transition ensures uniform material flow into the extrusion die.

5.2 Why temperature control matters

Extrusion temperature directly affects melt stability and flow consistency.

Temperatures that are too low can cause incomplete melting, while excessive heat can degrade the polymer.

Precise temperature control is required to maintain consistent filament quality and material properties.

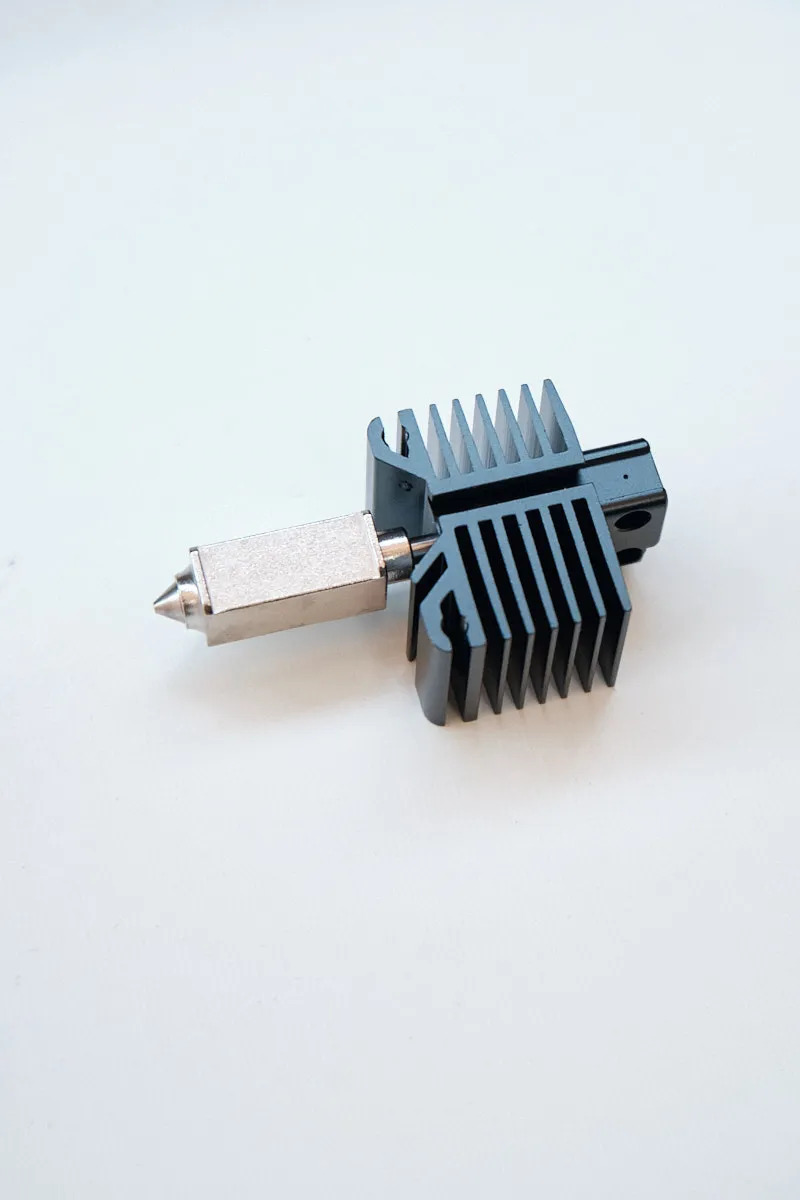

6. Extrusion & Water Cooling – Shaping the Filament

6.1 How filament diameter is initially formed

Molten material exits the extrusion die as a continuous strand.

The die geometry defines the initial filament diameter before cooling.

At this stage, the filament is still deformable and sensitive to pulling force.

6.2 Why cooling speed affects dimensional stability

Extrusion temperature directly affects melt stability and flow consistency.

Temperatures that are too low can cause incomplete melting, while excessive heat can degrade the polymer.

Precise temperature control is required to maintain consistent filament quality and material properties.

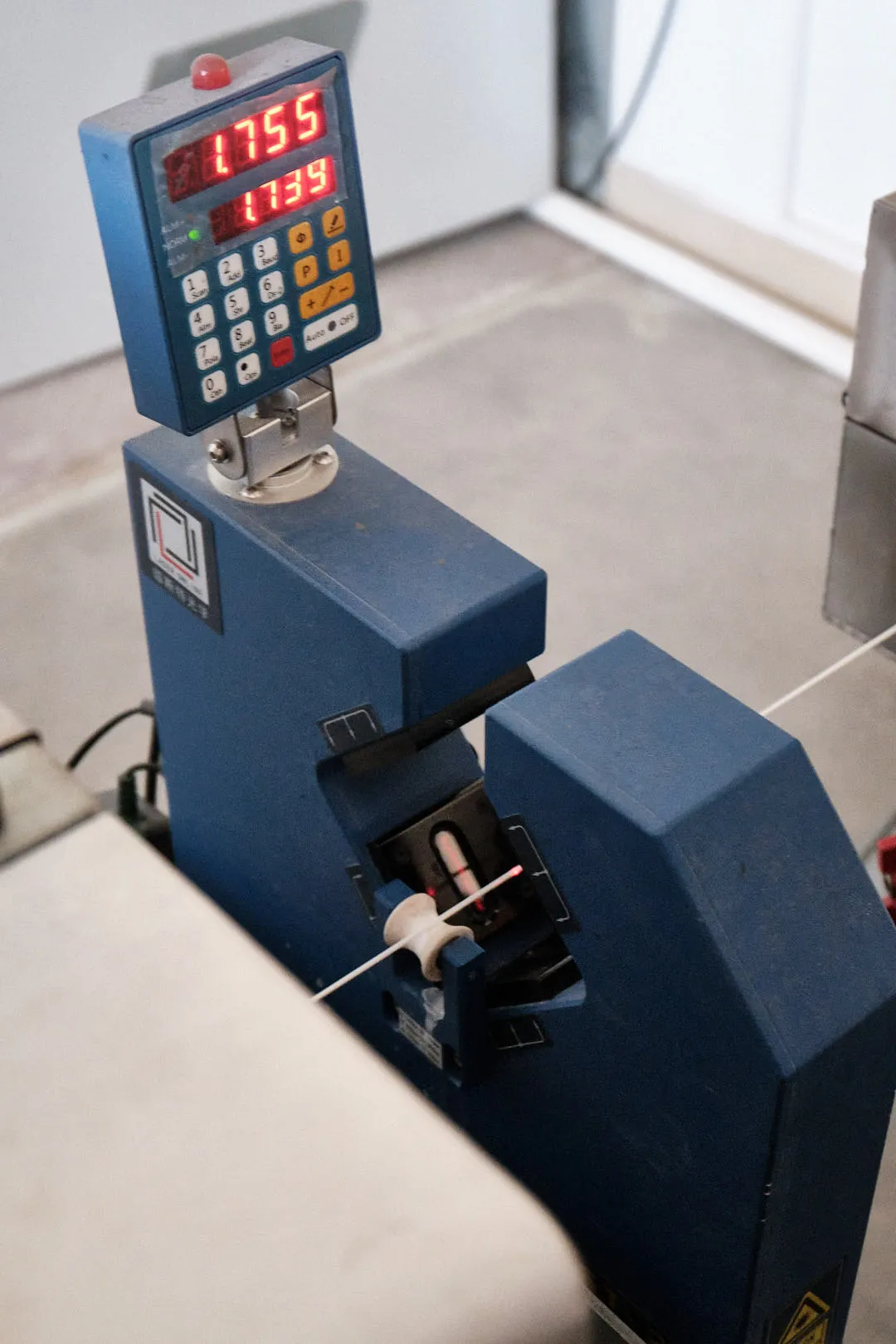

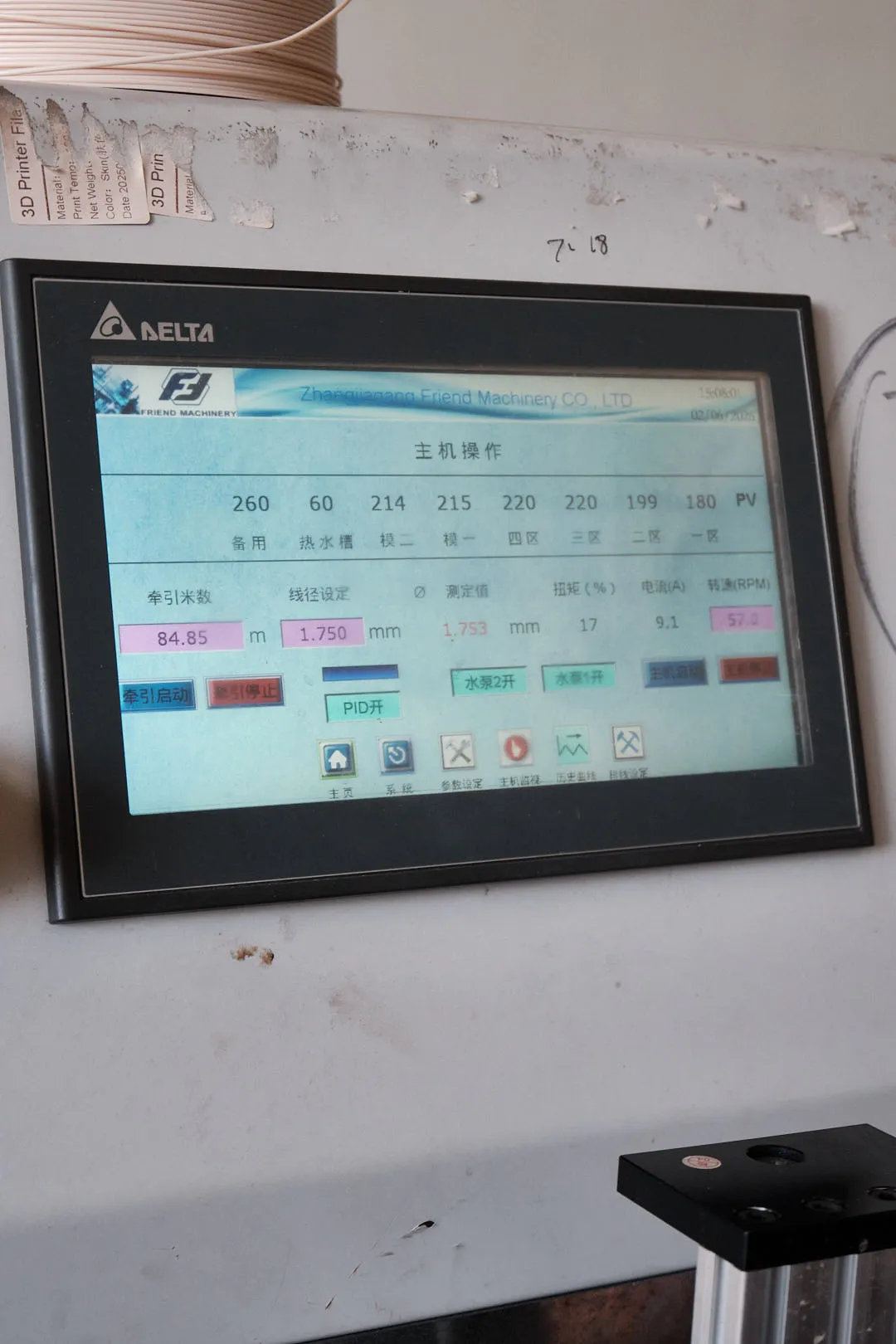

7. Laser Diameter Control – Where Precision Is Born

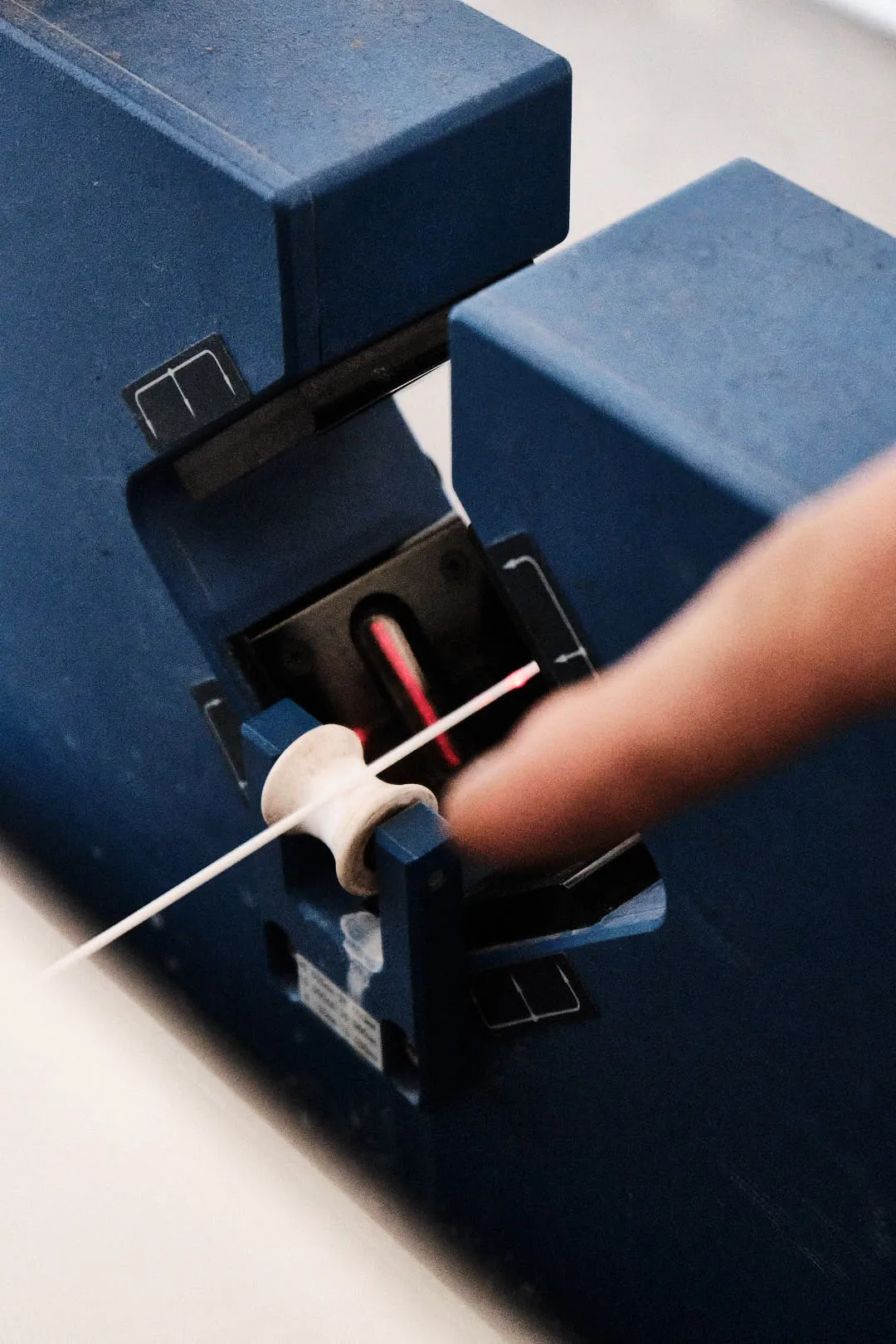

7.1 Real-time diameter measurement

After cooling, the filament passes through a laser measurement system that continuously monitors its diameter.

(At this stage, no additional drying is performed; moisture control is handled later through controlled handling and vacuum packaging.)

Measurements are taken in real time while the filament is moving, allowing immediate detection of any deviation.

7.2 Closed-loop feedback control

Diameter data is fed back to the extrusion and pulling system automatically.

The system adjusts line speed and tension in response to measured changes, maintaining dimensional stability throughout production.

7.3 Why ±0.02 mm tolerance is significant

Small diameter variations directly affect feeding reliability and extrusion consistency during printing.

Maintaining a tolerance of ±0.02 mm reduces the risk of under-extrusion, over-extrusion, and nozzle clogging, especially in high-speed or precision prints.

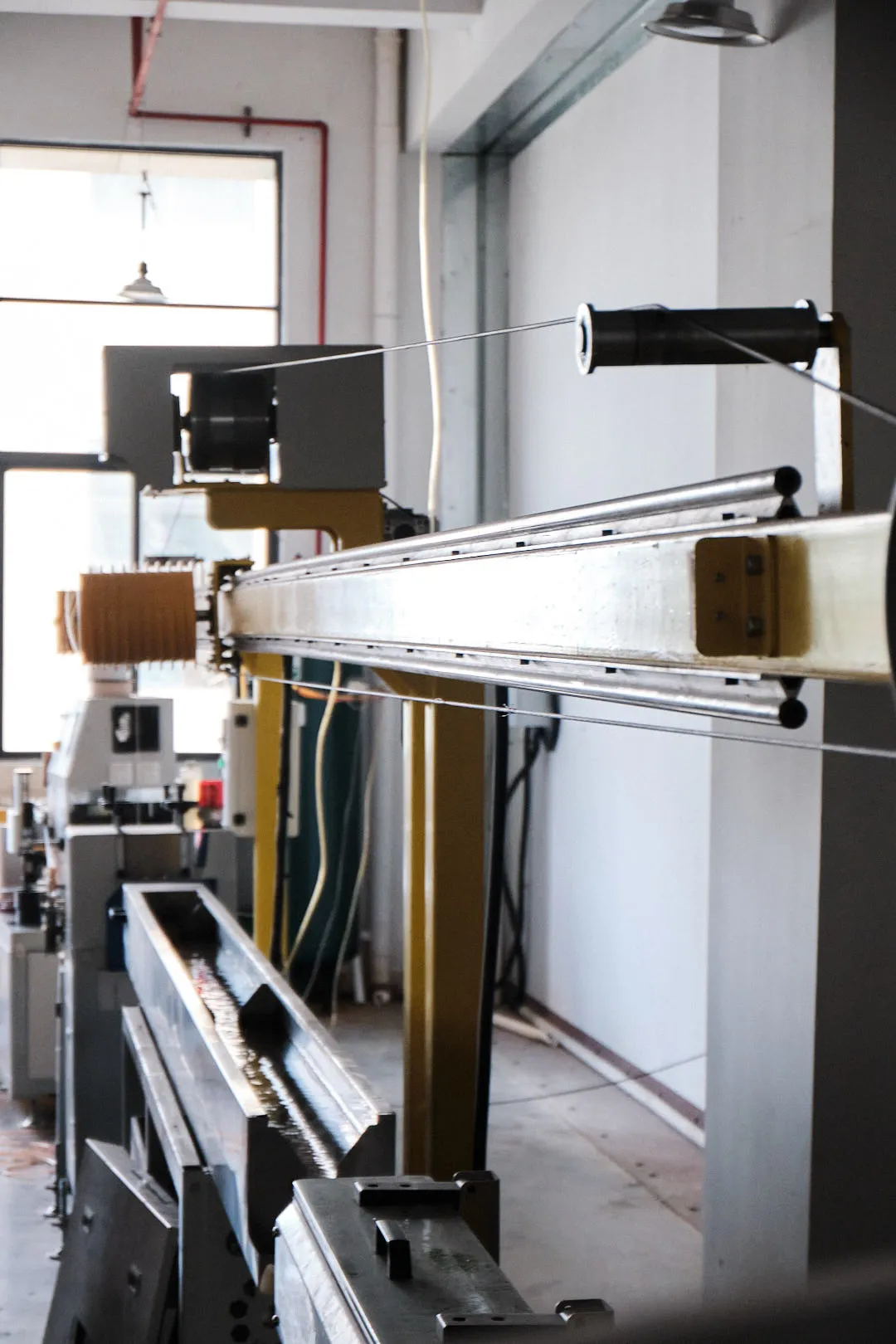

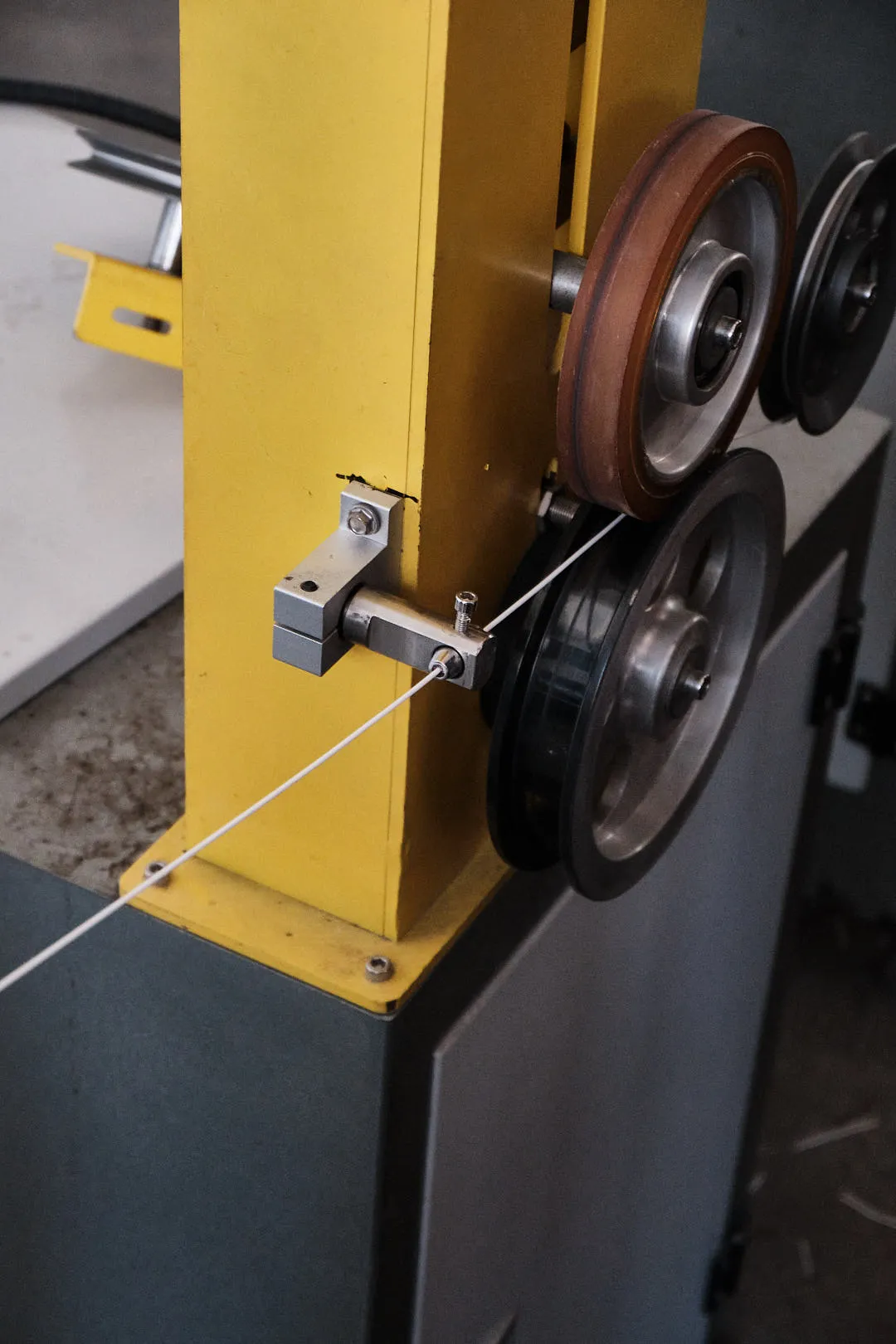

8. Spooling – More Important Than It Looks

8.1 Tension control during winding

After diameter control, the filament is wound onto spools under controlled tension.

Consistent tension prevents filament deformation and ensures even layering on the spool.

8.2 How winding quality affects print reliability

Uneven winding can cause tangles, snags, or inconsistent feeding during printing.

Proper spooling ensures smooth filament delivery from the spool to the extruder, reducing the risk of print interruptions.

9. Vacuum Packaging – Locking Quality In

9.1 Moisture protection after production

After spooling, filament is sealed in vacuum packaging to minimize exposure to ambient humidity.

Desiccants are included to maintain a low-moisture environment and prevent water absorption during storage and transport.

9.2 Shelf life and storage stability

Vacuum packaging helps preserve filament properties over extended storage periods.

By limiting moisture ingress, it reduces the risk of print defects when the filament is later opened and used.

10. Conclusion – Why Manufacturing Matters More Than Marketing

10.1 Same base material does not guarantee identical filament

Filaments made from the same polymer can perform very differently in practice.

Differences in material preparation, processing control, and quality standards lead to measurable variations in printing behavior and final part performance.

10.2 Process consistency as the key determinant of print quality

Stable, repeatable manufacturing processes are essential for producing reliable filament.

Consistent control at each stage—material handling, extrusion, measurement, and packaging—has a greater impact on print quality than material specifications alone.

OEM & Wholesale Filament Services by VoxelFuse3D

Private label and OEM filament manufacturing

VoxelFuse3D provides OEM and private label filament manufacturing for brands and distributors.

Services include material selection, color formulation, diameter specification, packaging, and branding, with production managed under controlled manufacturing standards.

Wholesale supply of established filament brands

VoxelFuse3D provides OEM and private label filament manufacturing for brands and distributors.

Services include material selection, color formulation, diameter specification, packaging, and branding, with production managed under controlled manufacturing standards.

Professional sourcing with stable pricing and quality assurance

VoxelFuse3D provides OEM and private label filament manufacturing for brands and distributors.

Services include material selection, color formulation, diameter specification, packaging, and branding, with production managed under controlled manufacturing standards.